- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

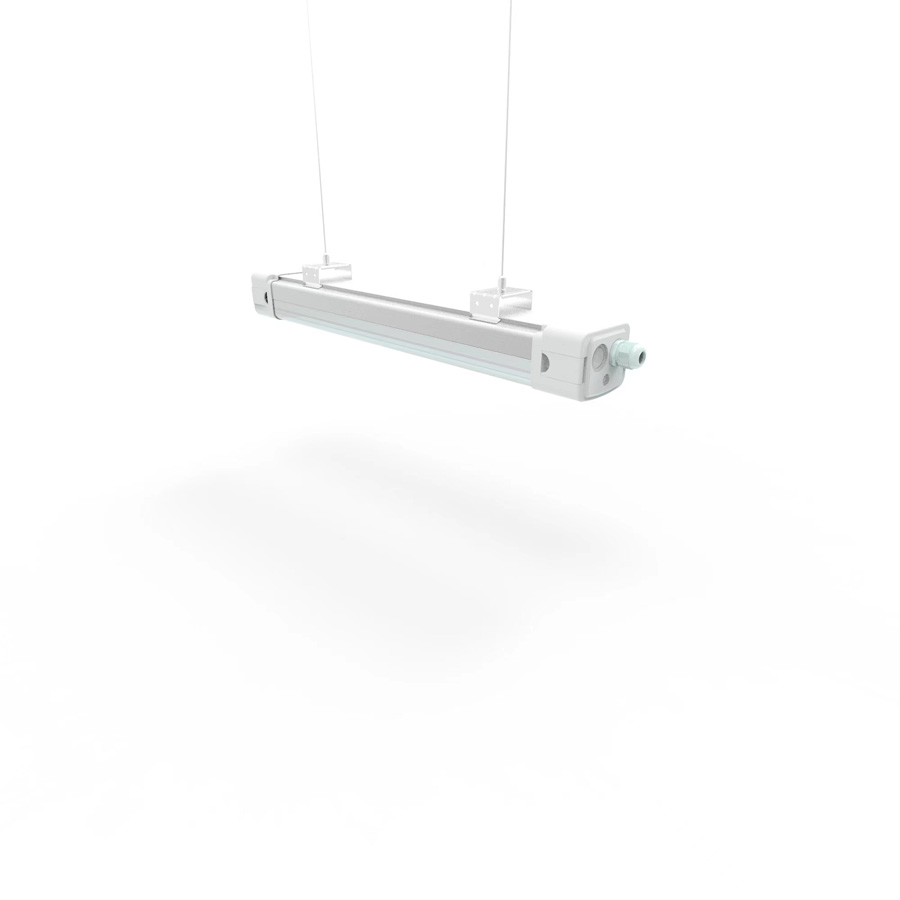

IP65 Tri-proof Fixture

The IP65 tri-proof fixture produced by JE, can fully meet all IP65 tri-proof lights factory requirements, and the service life of lamps can be greatly improved. At the same time, our production technology and creative aspects of manufacturing process keep up with the pace of scientific and technological development, we can provide OEM and ODM services according to different requirements of customers, and provide customers with satisfactory lighting solutions. The design and development of the IP65 tri-proof fixture enclosure is an extension of the ordinary lamp enclosure. Because in some special occasions, such as warehouse lighting, cold storage lighting, corridor lighting, gas station lighting, industrial lighting and other projects, the lamps are required to have the functions of waterproof, dust-proof and anti-corrosion.

Send Inquiry

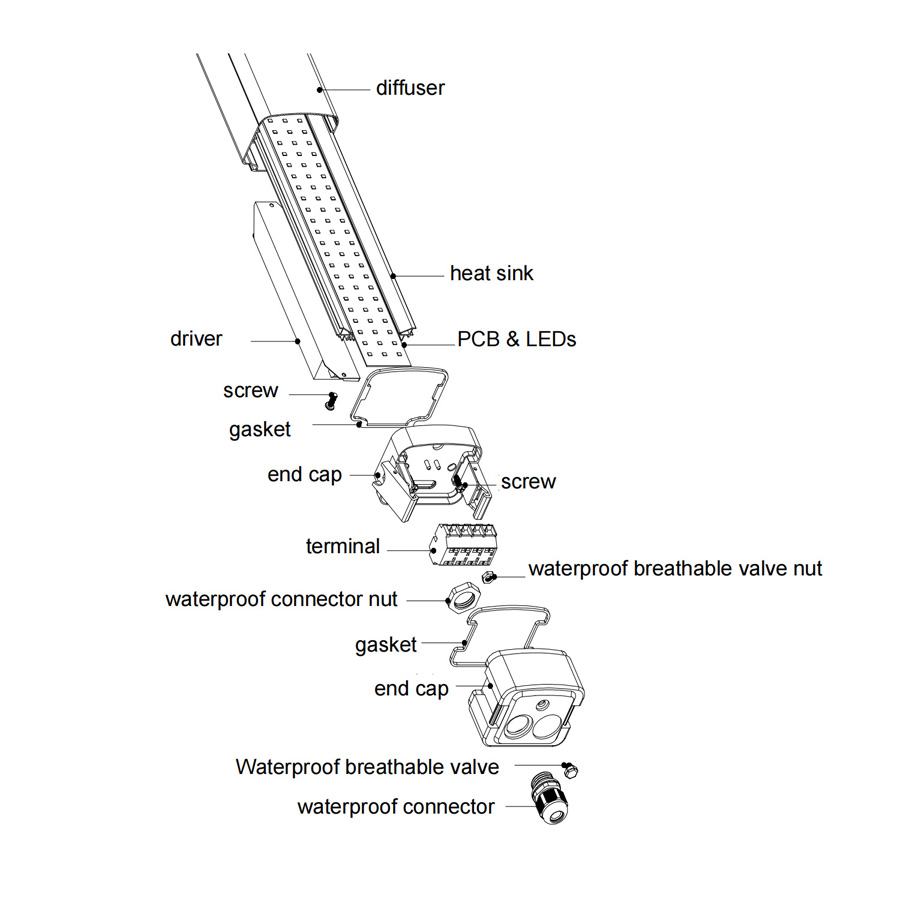

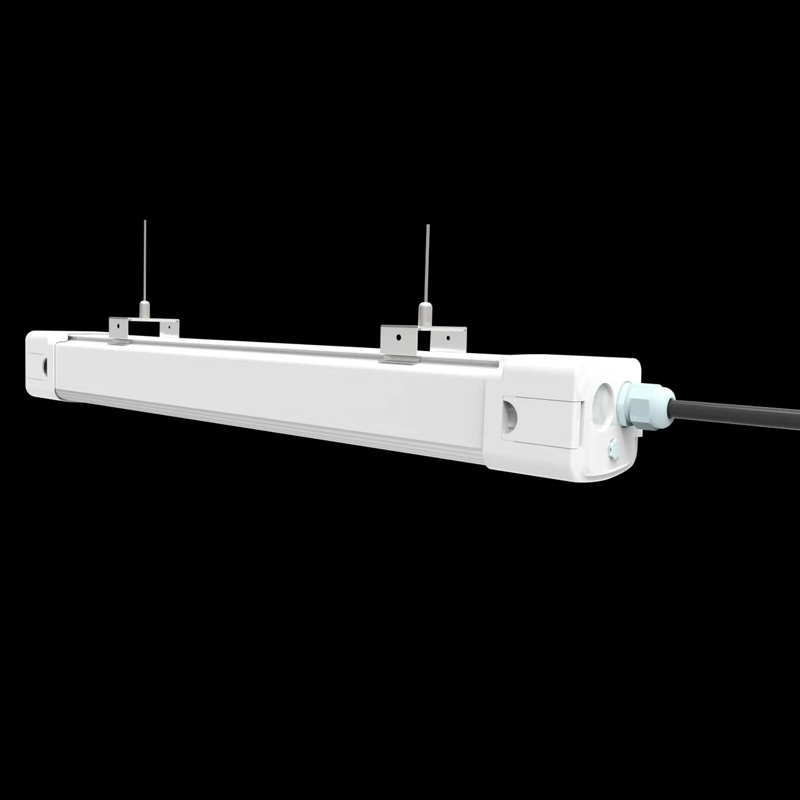

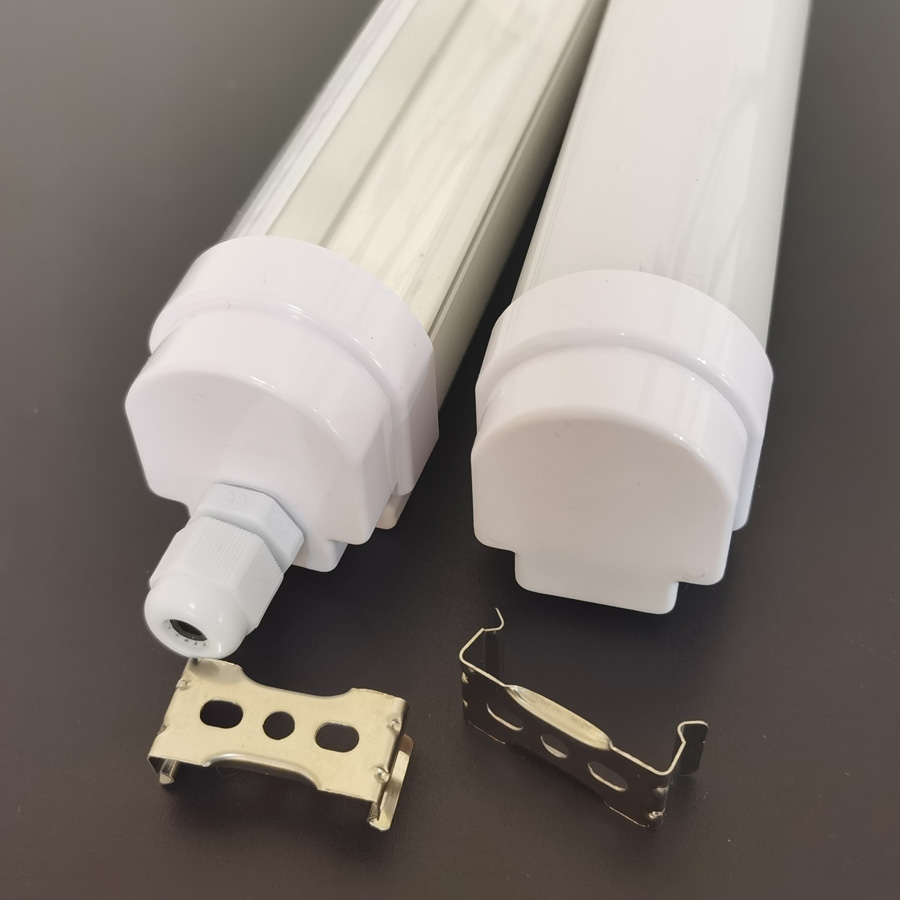

This is a brand-new IP65 tri-proof fixture designed by JE, the length can be customized according to customer requirements, and it has helped many LED tri-proof light manufacturers to provide many lighting solutions. This IP65 tri-proof fixture adopts the structure of plastic-coated aluminum, and the waterproof level is above IP65. The unique design of the breathing valve can ensure the heat dissipation of the lamp while waterproof. The installation is simple, compatible with surface or hanging installation, the whole lamp does not need to lead out the input wire, and the front plug of the clip can be opened by hand without tools, the mains is directly connected to the spare terminal, and then the buckle is closed to complete the installation.

Product Parameter (Specification)

|

Item NO. |

JE-608 |

|

Length |

1500mm customized |

|

Tube |

Tri-proof |

|

Size |

1500*83*68mm |

|

PCB board size |

1391*49*1mm |

|

Driver |

Internal |

|

Max height of driver |

25mm |

|

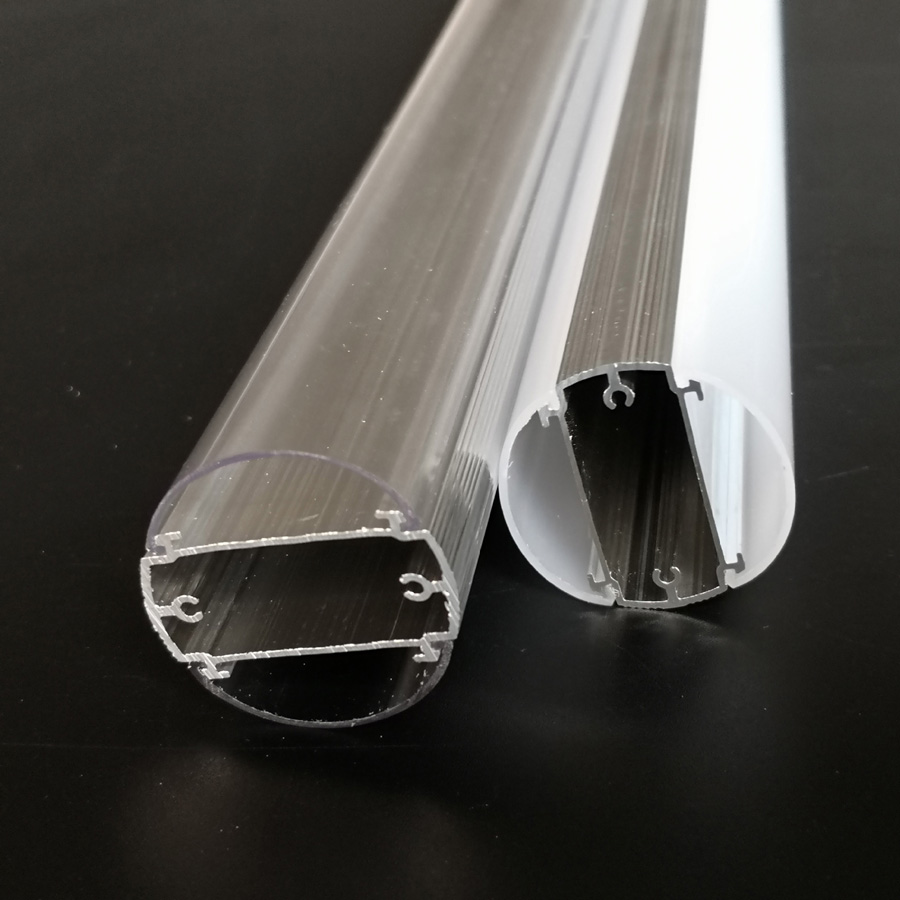

Aluminum material |

6063 aluminum alloy |

|

Aluminum base color |

Silver |

|

Plastic diffuser material |

Polycarbonate |

|

Plastic diffuser color |

Frosted, Clear(transparent) |

|

End caps |

Plastic |

|

Waterproof |

IP65 |

|

Structural components |

1,Lampshade*1 2,Heat sink*1 3 ,PCB* 1 4 Gasket *4 5, Plug*4 6, M4*15 Phillips pan head tapping screw* 4 7,Terminal*1 8,PG13.5 waterproof connector*1 9,Waterproof vent valve*1 10,Rubber stopper*1 11,PCB size: 49*1.0mm 12,Driver Height <25mm 13,PC color: transparent/ diffuser |

Product Feature And Application

IP65 LED tri-proof fixture can be made into many kinds of batten lights, this lights are generally used in retail stores, semi-outdoor ceilings, workshops, parking lots, public spaces and food processing plants.

Product Details

More details of this IP65 LED tri-proof fixture:

Product Qualification

Dongguan Jinen Lighting Technology Co., Ltd. is located in Dongguan City, Guangdong Province, the "world factory". The products we can produce include various special-shaped plastic profiles, PC round tubes for LED lighting, LED plastic tube diffusers, LED linear light housings, LED T5/T6/T8/T10/T12 tube housings, LED three-proof housings, LED LED aluminum profiles for light bars, etc. The materials we commonly process are PC, PMMA, ABS, PVC, etc. Most of the products are used in lighting, and some products are used in construction, decoration, packaging, toys, medical equipment and other industries.

Conventional products include T5 and T8 semi-aluminum and semi-plastic lamps, which are used to replace the previous fluorescent lights, used in underground garages, shopping malls, supermarkets, and schools' educational lighting renovations. The all-plastic aluminum-inserted lamp housing we supply meets the requirements of waterproof, dustproof and other occasions, and can reach the waterproof level of IP65; it can be made into plant lighting, used in plant factories or DIY by planting enthusiasts, and also it can be made into lamps for purification lighting in laboratories, cake gourmet shops, freezer lamps for freezers, etc...

Deliver,Shipping And Serving

FAQ

Q1. Where is your factory located?

Re: We are located in “World manufacturer” Dongguan city, Guangdong province, China.

Q2. How many machines are there in your factory?

Re: 20 of plastic extrusion production lines,

5 of aluminum extrusion production lines,

3 of injection molding machines,

5 of precision mold manufacturing equipments,

2 of test equipment(integrating sphere and Color Assessment Cabinet).

Q3. What are your normal processes for regular order?

Re: We are very suggest customers give the forecast for the next three month. This are our normal processes for regular order:

Receiving PO--Sales confirm PI with customer--Receiving 30% payment in advance--Sales assistant proceed production and confirms the exact LT--QC confirms the goods are ready for shipping--Receiving the balance payment--Arranging shipment--after sales service.

Q4. How do you ensure quality?

Re: At first, we use new raw material all with environment protection certifications, please be sure we don’t use any re-product raw material.

Second, we have a professional Quality Control department, both samples and finished products must be confirmed by QC before shipment.

Q5. How do you ensure leading time?

Re: We have a professional Product Material Control(PMC) department, all orders are arranged by system.