- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

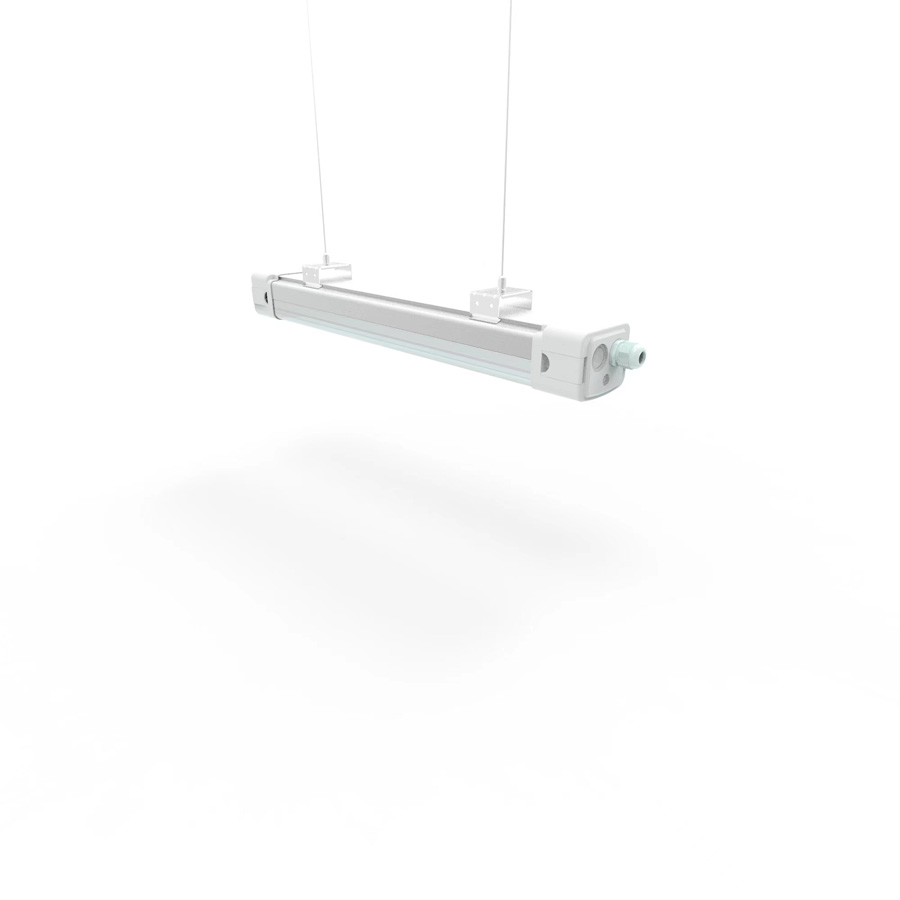

LED Batten Fixture

JE is a very high quality manufacturer of LED batten fixture in China. It can provide customers with dozens of LED batten fixture solutions to meet the needs of customers in different projects and projects. It has been rated as a high-quality supplier by customers for many times. The batten fixture is a kind of light tube housing, but it has more styles than the light tube housing, and the wattage is larger than that of the light tube. The general LED batten fixture is expensive than tubes, but many specific occasions will still prefer the solution of this fixture. For more information of LED batten fixture, warmly welcome to contact us.

Send Inquiry

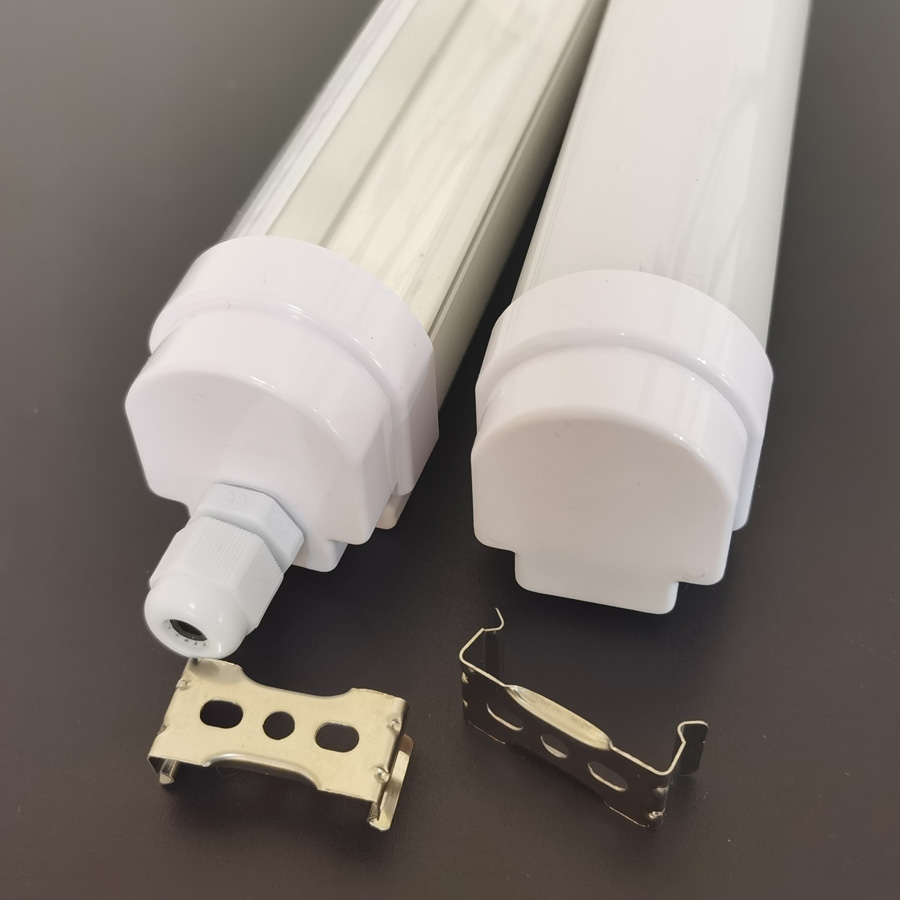

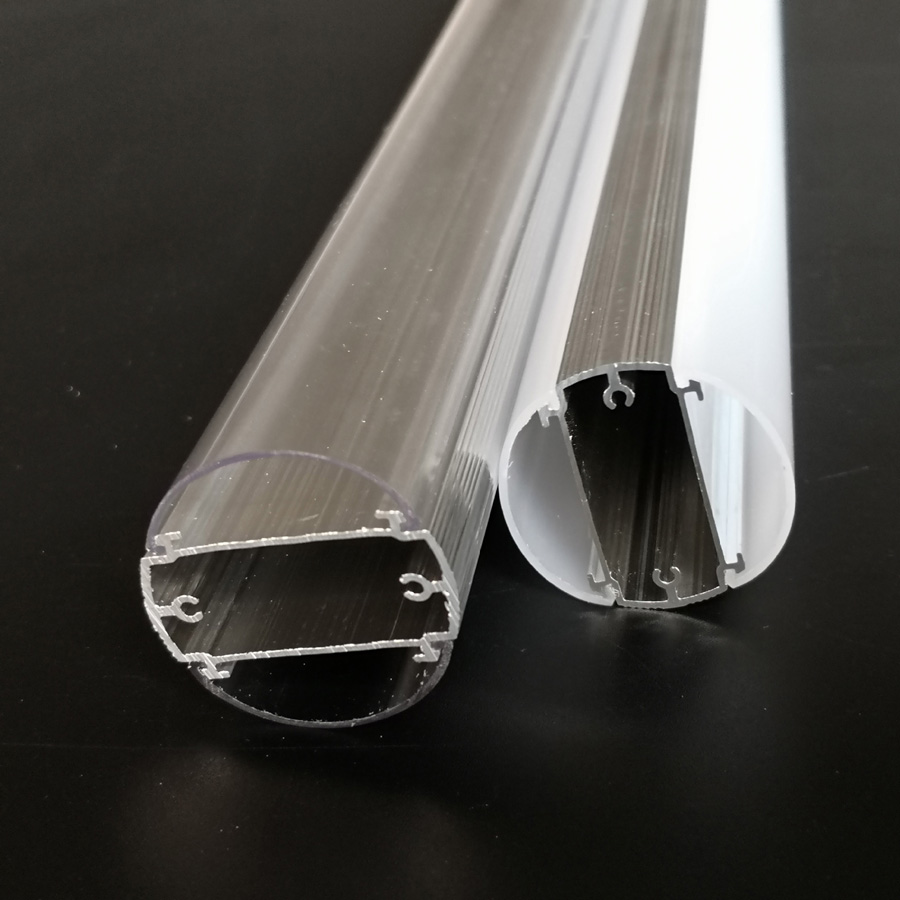

JE's this LED batten fixture was developed and recognized by many LED batten lights factories. This LED batten fixture adopts a plastic-coated aluminum structure, that is, the outer tubes are all plastic, and there is an aluminum profile inside, which is used to install the PCB board, which can help the lamp beads to dissipate heat. The advantage of this structure is that the price is relatively low, and the shell is an integrated structure, the protection function is stronger. Our company uses 100% new raw materials to ensure high light transmittance and stable diffusion effect of the plastic diffuser.

Product Parameter (Specification)

|

Item NO. |

JE-606 |

|

Length |

900mm customized |

|

Tube |

Tri-proof |

|

Size |

900*83*68mm |

|

PCB board size |

791*49*1mm |

|

Driver |

Internal |

|

Max height of driver |

25mm |

|

Aluminum material |

6063 aluminum alloy |

|

Aluminum base color |

Silver |

|

Plastic diffuser material |

Polycarbonate |

|

Plastic diffuser color |

Frosted, Clear(transparent) |

|

End caps |

Plastic |

|

Waterproof |

IP65 |

|

Structural components |

1,Lampshade*1 2,Heat sink*1 3 ,PCB* 1 4 Gasket *4 5, Plug*4 6, M4*15 Phillips pan head tapping screw* 4 7,Terminal*1 8,PG13.5 waterproof connector*1 9,Waterproof vent valve*1 10,Rubber stopper*1 11,PCB size: 49*1.0mm 12,Driver Height <25mm 13,PC color: transparent/ diffuser |

Product Feature And Application

LED batten fixture can be made into many kinds of batten lights, this lights are generally used in power plants, steel, petrochemicals, ships, stadiums, parking lots, basements, etc.

Product Details

More details of this IP65 LED batten fixture:

Product Qualification

Dongguan Jinen Lighting Technology Co., Ltd. is located in Dongguan City, Guangdong Province, the "world factory". As a professional OEM&ODM LED aluminum profile and LED plastic profile extrusion manufacturer, we have more than 500 kinds of public mold products and more than 2,000 customized private mold products. It has become a leading enterprise in the industry and is deeply trusted and supported by customers. In order to improve production efficiency, we have carried out one-out-two technical upgrades for products with very large orders, which greatly improves production efficiency, reduces costs for customers, and achieves a win-win situation.

The products we can produce include various special-shaped plastic profiles, PC round tubes for LED lighting, LED plastic tube diffusers, LED linear light housings, LED T5/T6/T8/T10/T12 tube housings, LED three-proof housings, LED LED aluminum profiles for light bars, etc. The materials we commonly process are PC, PMMA, ABS, PVC, etc. Most of the products are used in lighting, and some products are used in construction, decoration, packaging, toys, medical equipment and other industries.

Deliver,Shipping And Serving

FAQ

Q1. Where is your factory located?

Re: We are located in “World manufacturer” Dongguan city, Guangdong province, China.

Q2. How many days is the tool production of LED aluminum and plastic profile?

Re: Usually 7-15 days.

Q3. Can Your products be installed under the cold weather?

Re: Yes, Weather resistance is -40 degree to 120 degree.

Q4. What are your normal processes for regular order?

Re: We are very suggest customers give the forecast for the next three month. This are our normal processes for regular order:

Receiving PO--Sales confirm PI with customer--Receiving 30% payment in advance--Sales assistant proceed production and confirms the exact LT--QC confirms the goods are ready for shipping--Receiving the balance payment--Arranging shipment--after sales service.

Q5. How many machines are there in your factory?

Re: 20 of plastic extrusion production lines,

5 of aluminum extrusion production lines,

3 of injection molding machines,

5 of precision mold manufacturing equipments,

2 of test equipment(integrating sphere and Color Assessment Cabinet).