- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

LED Plastic Profiles for T8 Tube Light Housing

As a high-quality LED tube housing manufacturer, JE has more than 500 kinds of public mold products and more than 2,000 kinds of private mold products customized for customers. The styles of LED tube shells are complete, which can meet the needs of various LED outer tube designs. This LED Plastic Profiles for T8 tube light housing can be made non-waterproof or waterproof. It adopts the design structure of plastic-coated aluminum, and the cost of the entire raw material is much cheaper than that of half-aluminum and half-plastic. Because the aluminum material inside is thicker than the general insert aluminum, the wattage that can be made is relatively high. Our company has a variety of T8 lamp shell styles, you are welcome to consult at any time.

Send Inquiry

1. Products Introduction

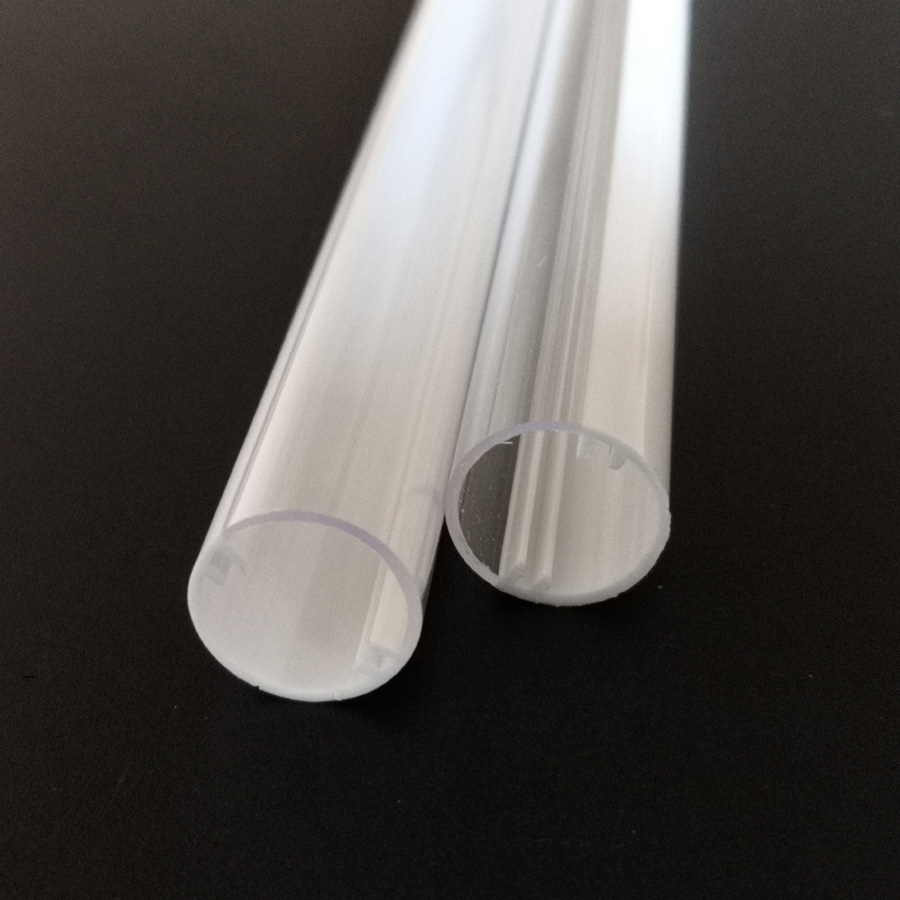

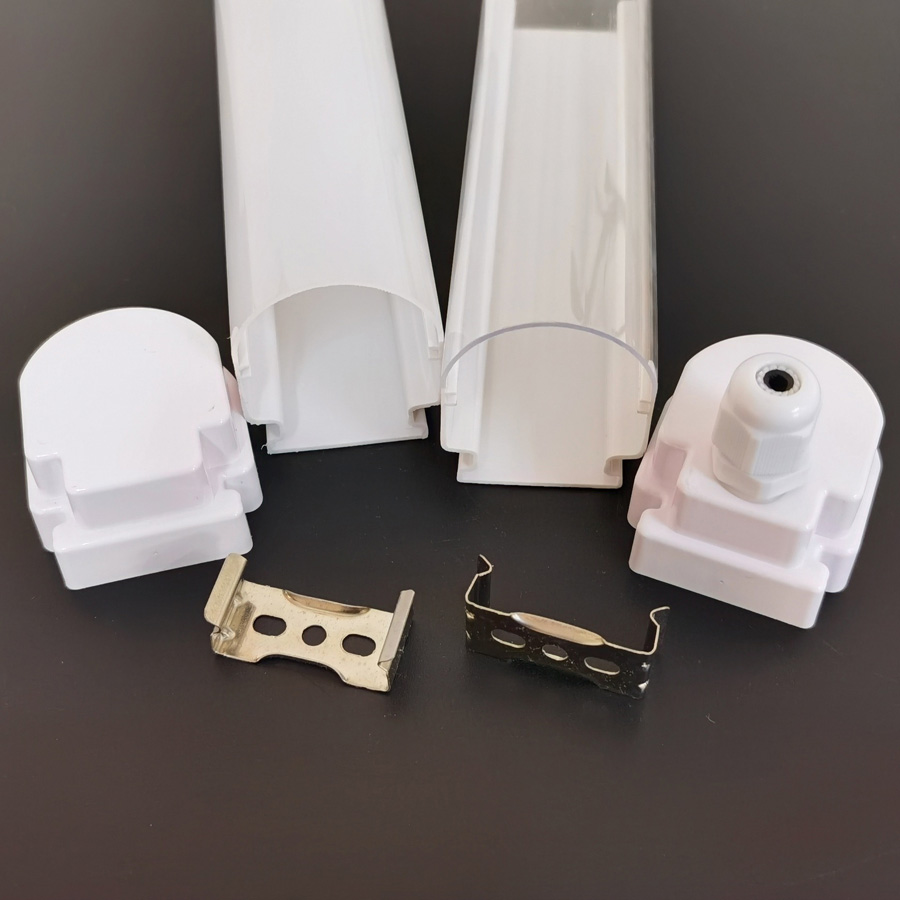

JE produces a complete range of LED tube housings, which can provide you with a one-stop purchasing solution. The shell of this JE-35 LED Plastic Profiles for T8 tube light housing is pure polycarbonate, there are many advantages: 85%-95% High light transmittance; -30 -120 ℃high cold resistance; with very good flexibility, strong impact resistance, not easy to deform.

And there is also a aluminum base in PC tube, we use high-quality thickened aluminum profiles that is very suitable for heat dissipation; the surface is oxidized, the smoothness is high; and aluminum tube without black, no water marks.

2.Product Parameter (Specification)

|

Item NO. |

JE-35 |

|

Length |

600mm, 900mm, 1200mm, 1500mm, 2400mm or customized |

|

Tube |

T8 |

|

Diameter |

26mm |

|

PCB board size |

19*1.0mm |

|

Driver |

Internal |

|

Max height of driver |

13mm |

|

Aluminum base material |

6063 aluminum alloy |

|

Aluminum base color |

Silver |

|

Plastic tube material |

Polycarbonate |

|

Plastic tube color |

Frosted, Clear(transparent) |

|

End caps |

Plastic |

|

Waterproof |

IP20 or IP65 |

3.Product Feature And Application

This JE-35 LED Plastic Profiles for T8 tube light housing is widely used in store, office, auditorium, show room, class room, supper market and so on.

4. Product Details

More details of this JE-35 LED Plastic Profiles for T8 tube light housing:

5. Product Qualification

As a LED Aluminum Profile and LED plastic profile professional manufacturer, here are our main machines:

1.20 plastic extrusion machines,

2.5 aluminum extrusion machines,

3.3 of injection molding machines,

4.5 of precision mold manufacturing equipment,

5.A professional integrating sphere to test whether the lamps made by our lamp kit can meet the various indicators required by customers,

6.A professional standard light source testing equipment for testing the light transmittance and other properties of plastic lampshades.

JE always focus on product qualification from aluminum and plastic raw material to extrusion production line, from samples quality control to mass production control, from strong perfect package to whole-heart service.

6. Deliver,Shipping And Serving

7.FAQ

Q4. How do you ensure quality?

Re: At first, we use new raw material all with environment protection certifications, please be sure we don’t use any re-product raw material.

Second, we have professional Quality Control department, both samples and finished products must be confirmed by QC before shipment.

Q5. What kinds of LED lighting can use your profiles?

Re: LED cabinet lighting, LED strip lights, T5/T6/T8/T10/T12 tubes, tri-proof tubes and special-shape tubes,

Q3. How are you products installed?

Re: We have recessed mounted type and surface mounted type, there are a little difference for each pro

Q4. Do you have any products for LED strips?

Re: Yes, we have many kinds of LED aluminum profiles for LED st

Q5. What is process of OEM order?

Re: Receiving drawing--Project manage confirm all production details with customer--Receiving tool production PO--Sales assistant proceed tool production--QC confirm samples are ready for shipping--Project manage confirm products with customer about every details-- start the regular order.