- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

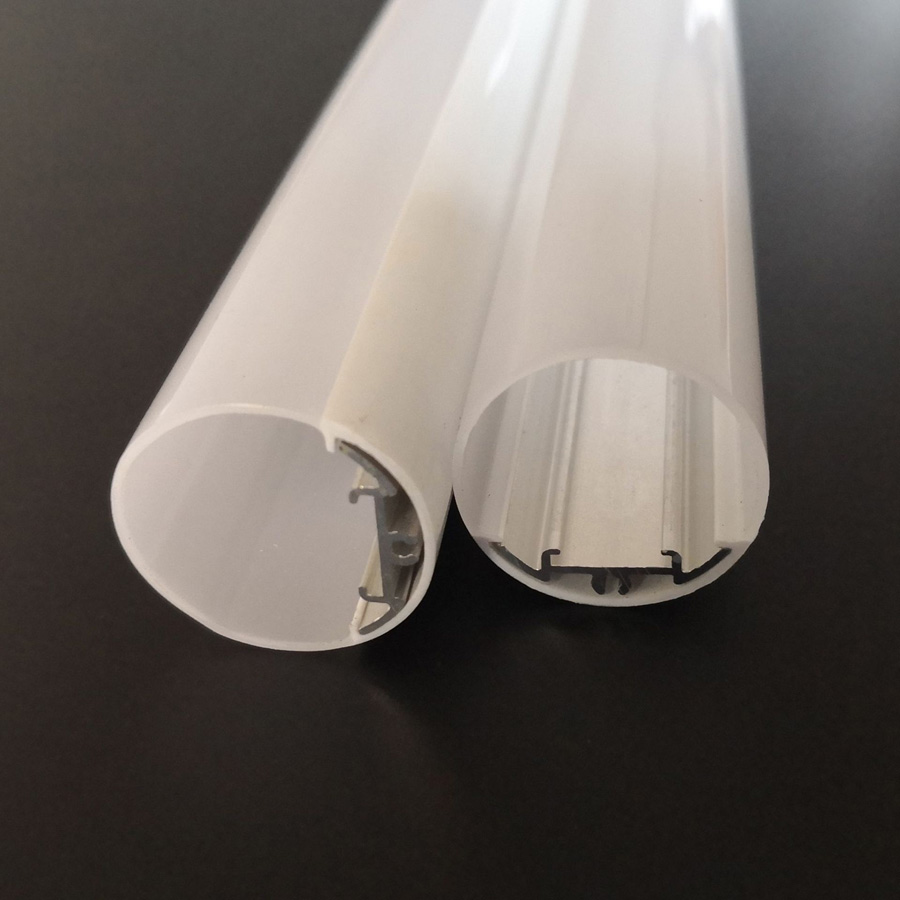

1.2m LED Tube Housing

As the 1.2m LED Tube Housing Manufacturer, In the T8 LED tube housing, the best heat dissipation is semi-aluminum and semi-plastic structure. Because of the good heat dissipation effect, the wattage can be relatively high, so it is very suitable for the design scheme with high lumen requirements for indoor lighting projects. JE is a professional LED tube housing manufacturer, in addition to this kind of regular tube housing, we also provide OEM and ODM manufacturing for customers, providing professional linear lighting design solutions.

Send Inquiry

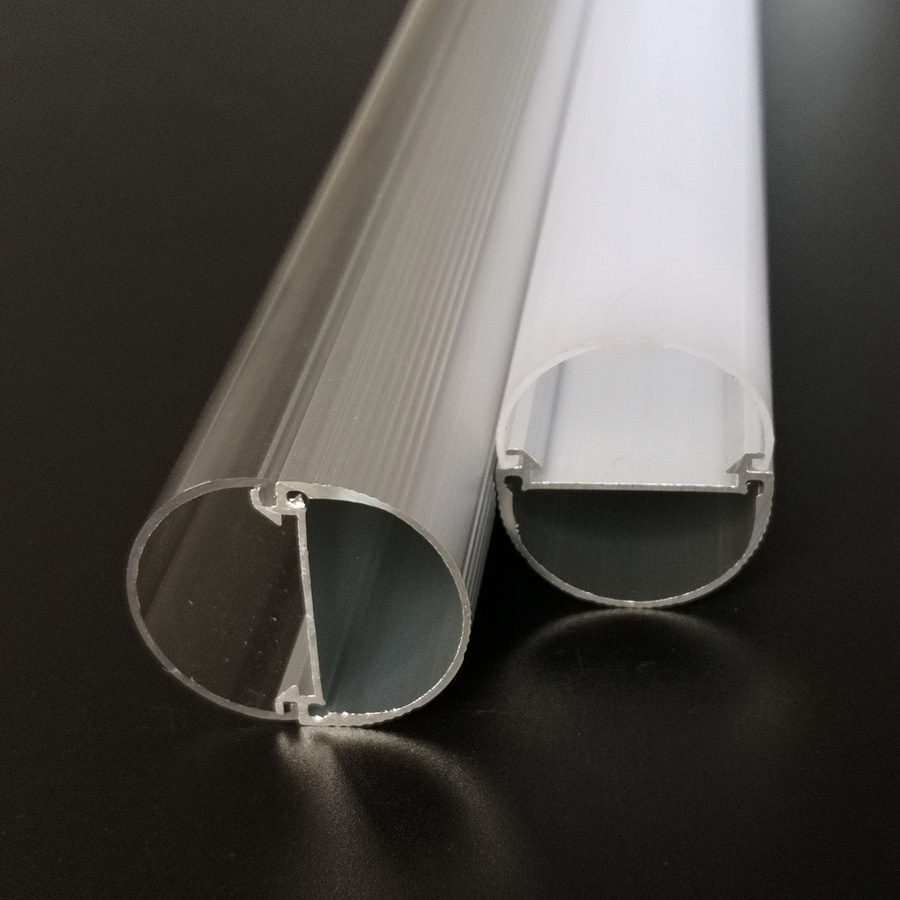

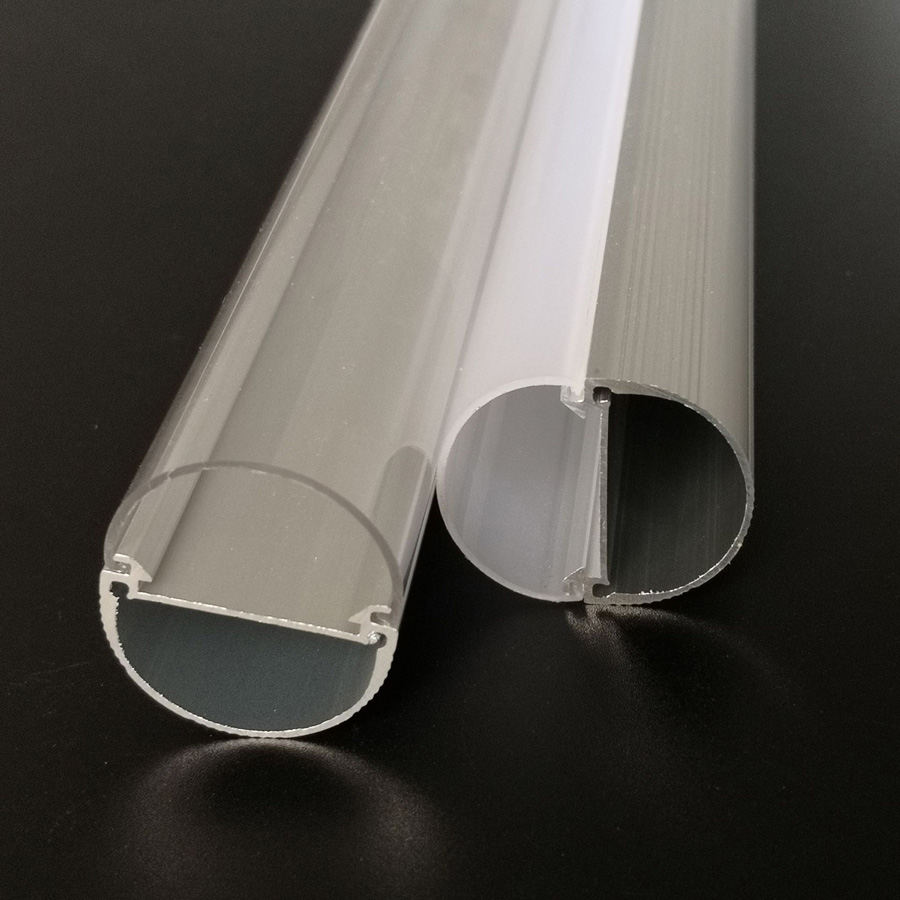

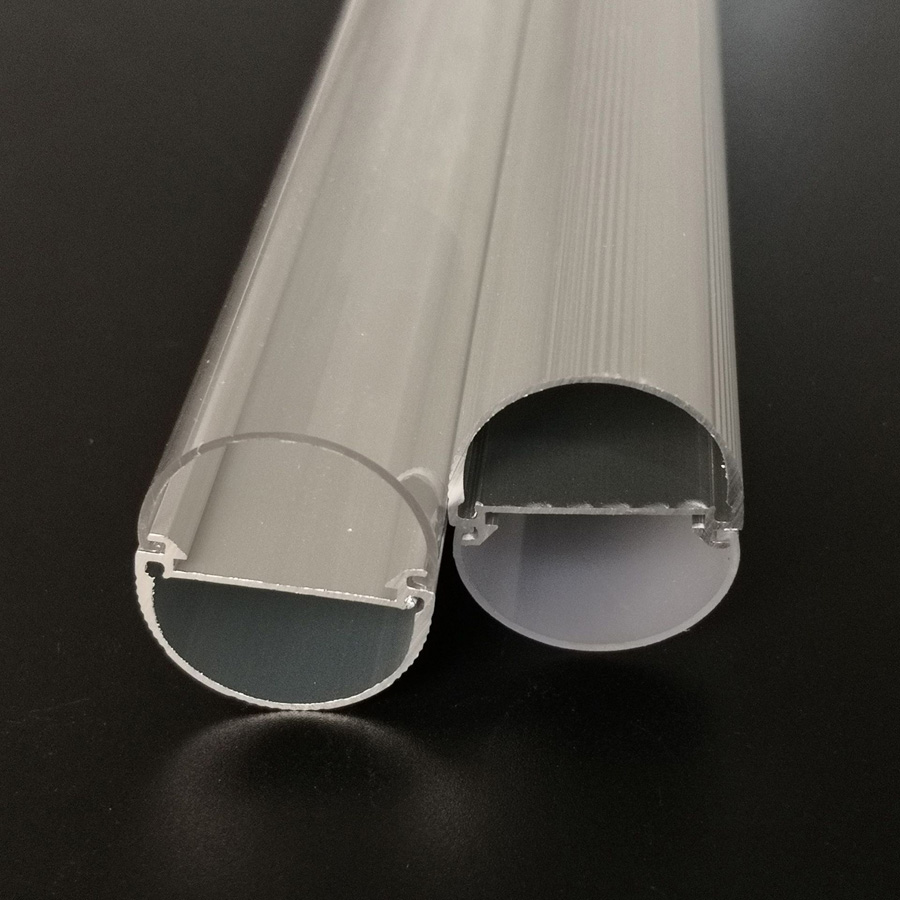

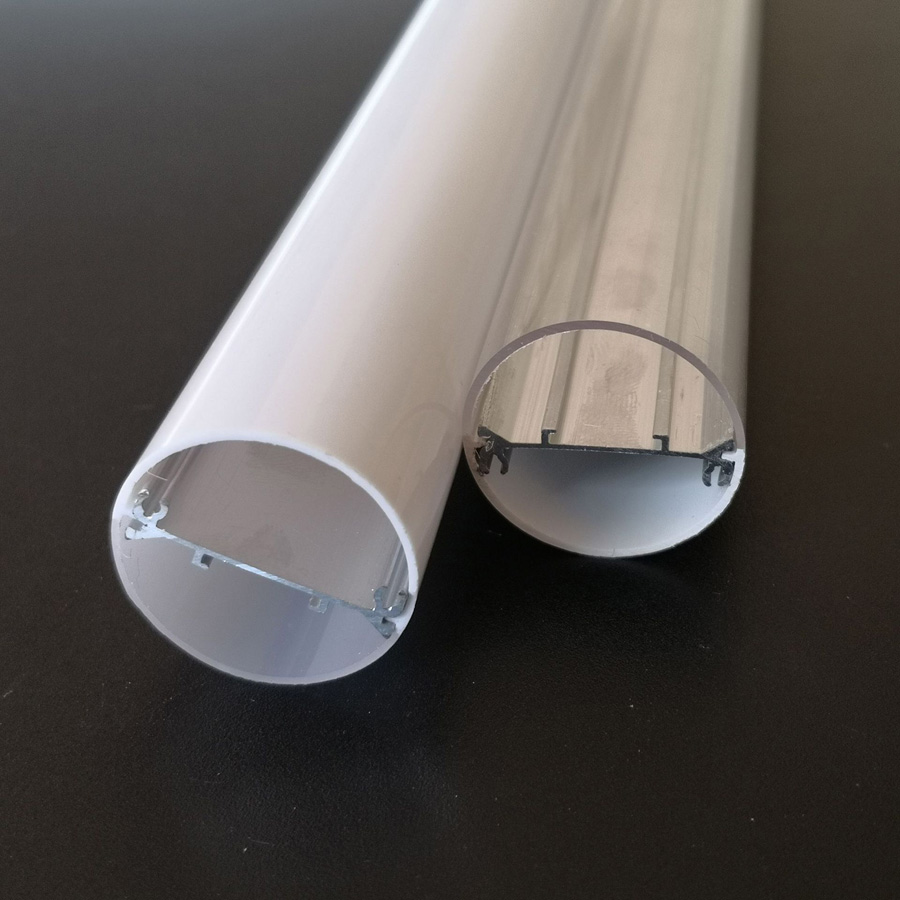

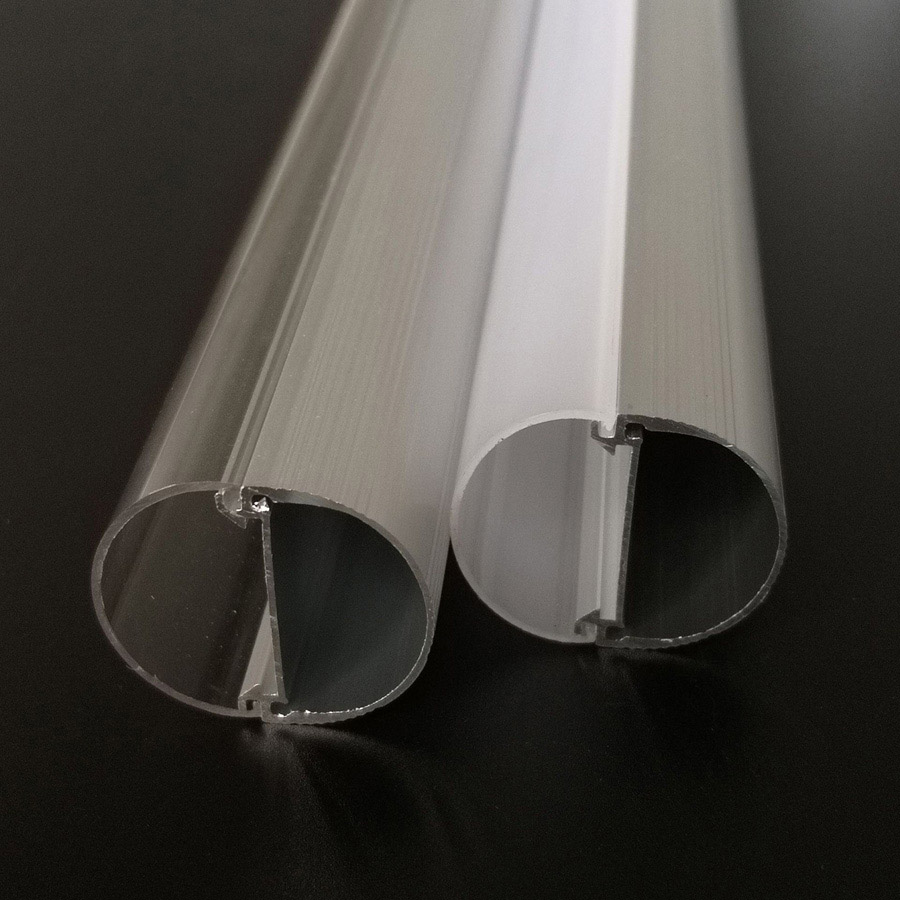

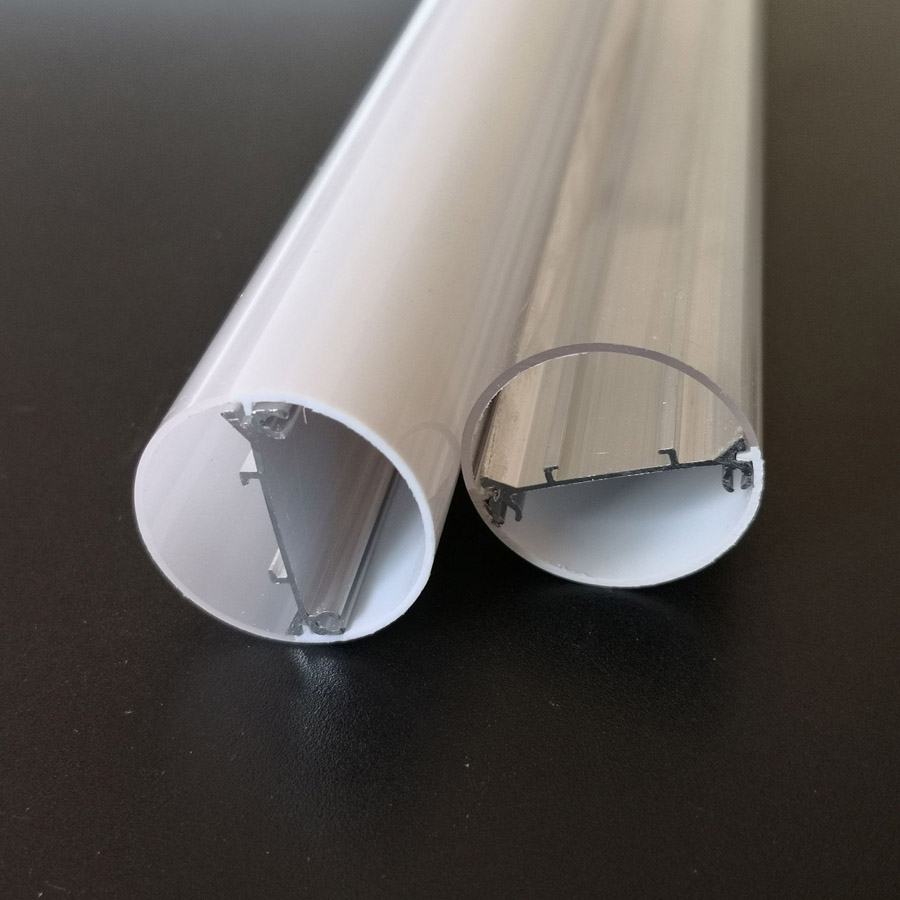

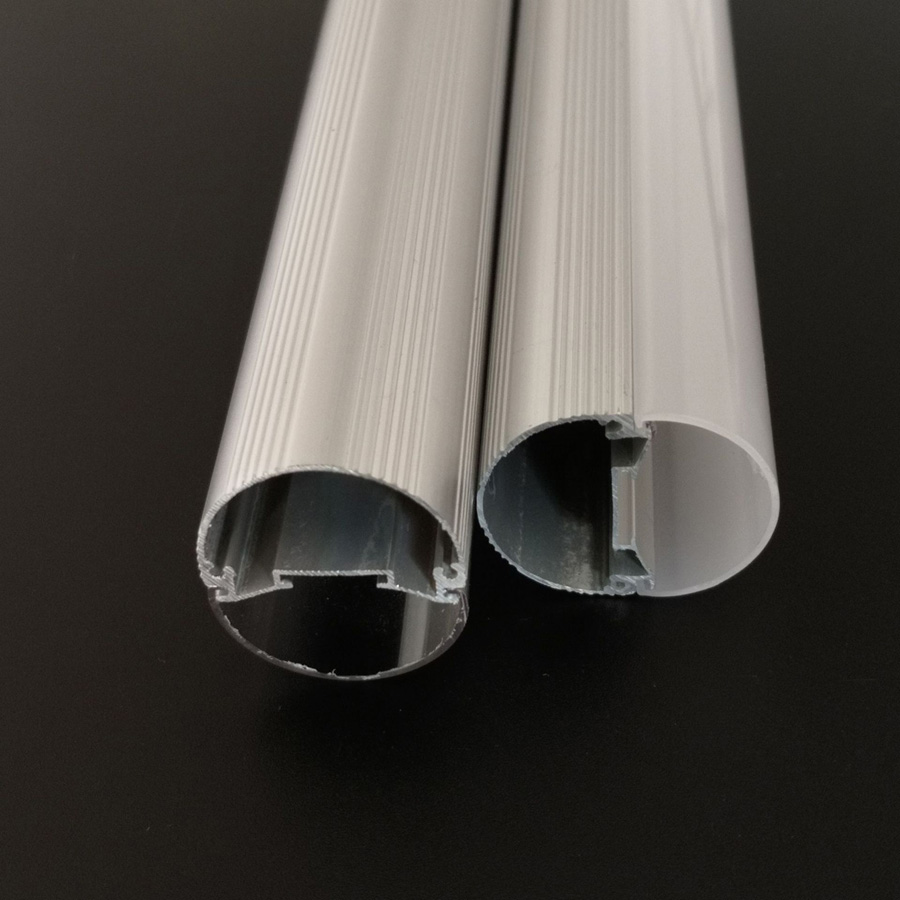

This T8 housing is oval, the upper part is a PC diffuser cover, using 100% new raw material polycarbonate, the light transmittance of milky white can reach more than 85%, the surface has no scratches, and it is not easy to yellow. The lower part is made of 6063-T5 aluminum raw material, and the surface is anodized after extrusion production, which will not deform or rust. This aluminum profile is heavier than normal and has better heat dissipation, so it can be designed with a higher wattage. The size of the PCB board is 19*1mm. If a smaller patch is used, double-row lamp beads can be designed. As a high-quality LED lamp housing manufacturer, our company has always won the trust of customers with excellent product quality and professional service awareness.

1.2m LED Tube Housing Parameter (Specification)

|

Length |

600mm, 900mm, 1200mm, 1500mm, 2400mm or customized |

|

Tube |

T8 |

|

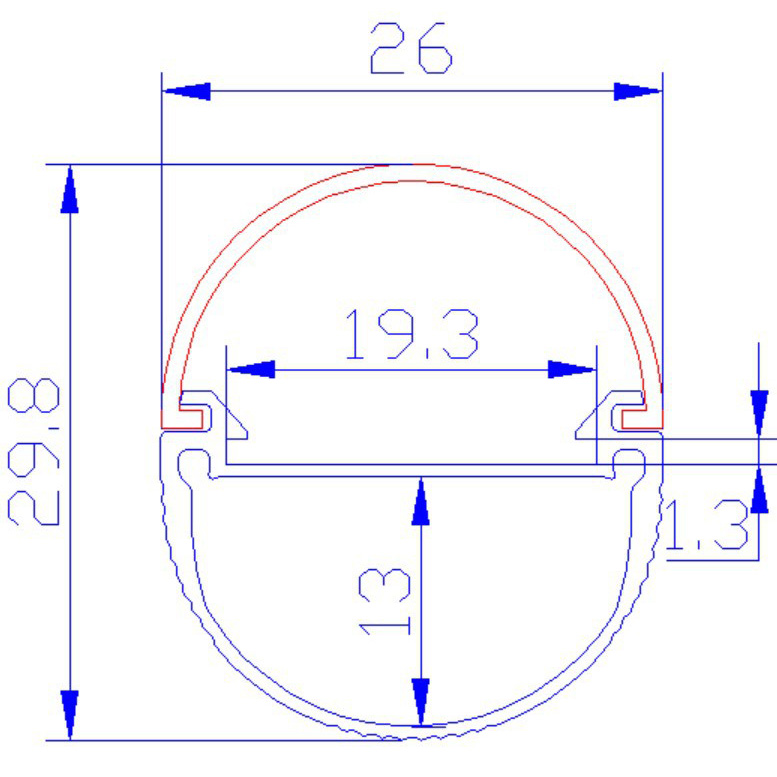

Diameter |

26mm |

|

PCB board size |

19*1.2mm |

|

Driver |

Internal |

|

Max height of driver |

12mm |

|

Aluminum base material |

6063 aluminum alloy |

|

Aluminum base color |

Silver |

|

Plastic diffuser material |

Polycarbonate |

|

Plastic diffuser color |

Frosted, Clear(transparent), stripe |

|

End caps |

Plastic(screwing) |

|

Waterproof |

IP20 |

1.2m LED Tube Housing Feature And Application

This LED tube housing is mainly used for School lighting, factory lighting, convenience store lighting, home lighting, shopping mall lighting, office lighting and more.

Product Details

More details of this LED tube housing:

Product Qualification

As a professional manufacturer of LED aluminum profiles and LED plastic profiles, the following are our main machines:

1.20 Plastic extruder

2.5 aluminum extrusion press,

3. Professional integrating spheres test whether the lamps made by our lighting kit can meet the various indicators required by customers,

4. Professional standard light source testing equipment for testing the light transmittance and other properties of plastic lampshades.

From aluminum-plastic raw materials to extrusion production lines, from sample quality control to mass production control, from powerful perfect packaging to wholehearted service, JE always focuses on product quality.

Deliver,Shipping And Serving

FAQ

Q1. Where is your factory located?

Re: We are located in “World manufacturer” Dongguan city, Guangdong province, China.

Q2. Is the mold opening cost borne by the customer or your factory?

Re: Customers pay the cost first, after the quantity is more than 50000 meters for total order, the tool cost can be deducted in order.

Q3. Do you provide sample? Free or charge?

Re: Yes, we charge for samples.

Q4. What are your normal processes for regular order?

Re: We are very suggest customers give the forecast for the next three month. This are our normal processes for regular order:

Receiving PO--Sales confirm PI with customer--Receiving 30% payment in advance--Sales assistant proceed production and confirms the exact LT--QC confirms the goods are ready for shipping--Receiving the balance payment--Arranging shipment--after sales service.

Q5. What is process of OEM order?

Re: Receiving drawing--Project manage confirm all production details with customer--Receiving tool production PO--Sales assistant proceed tool production--QC confirm samples are ready for shipping--Project manage confirm products with customer about every details-- start the regular order.