- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

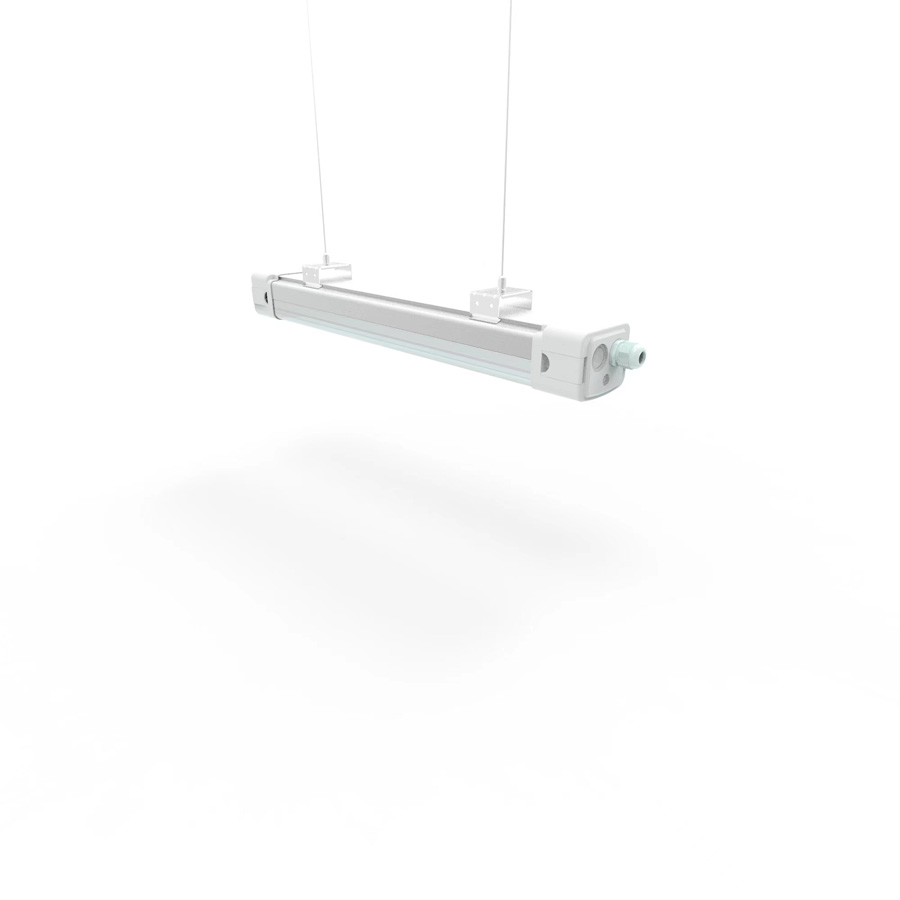

LED Waterproof Batten Light Housing

The LED waterproof batten light housing is the main tri-proof light product of JE Company, and it is also a product that is highly recognized by domestic and foreign LED waterproof batten lights. Because no matter in terms of quality, details, or packaging, JE’s LED waterproof batten light housings are among the best in the industry. We can not only provide customers with a single LED waterproof batten light housing, but also provide customers with customized PCB, LEDs and inner and outer packaging of the entire light. This one-stop service gives our customers a very good experience.

Send Inquiry

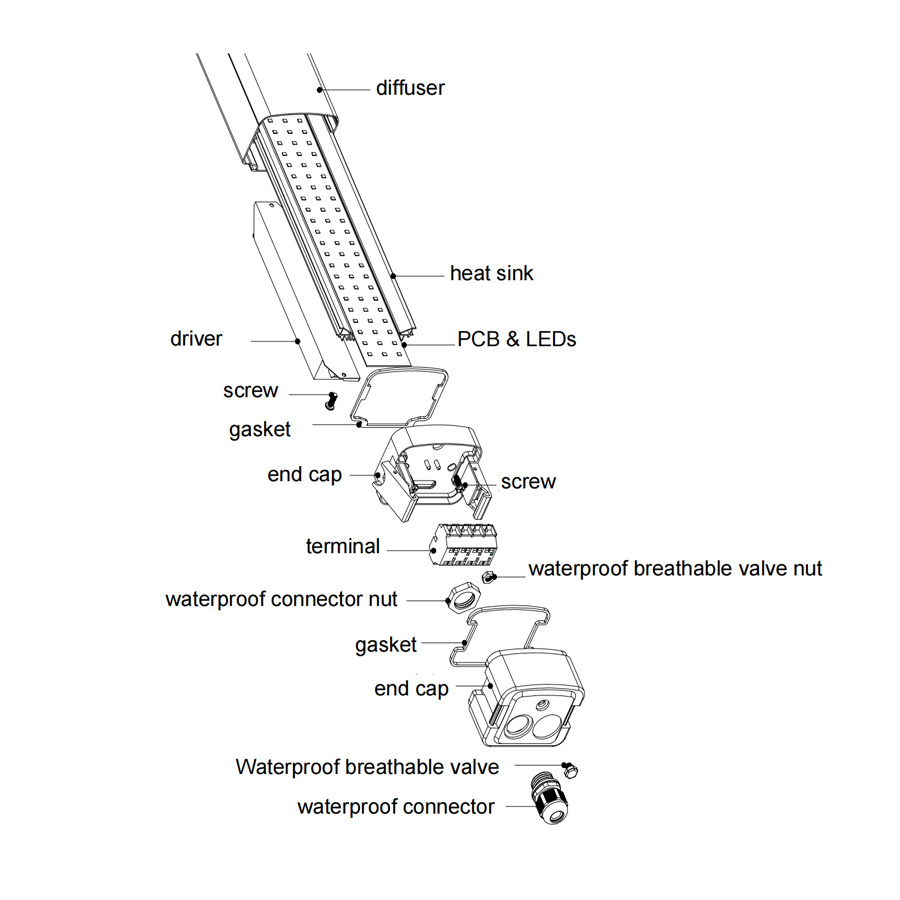

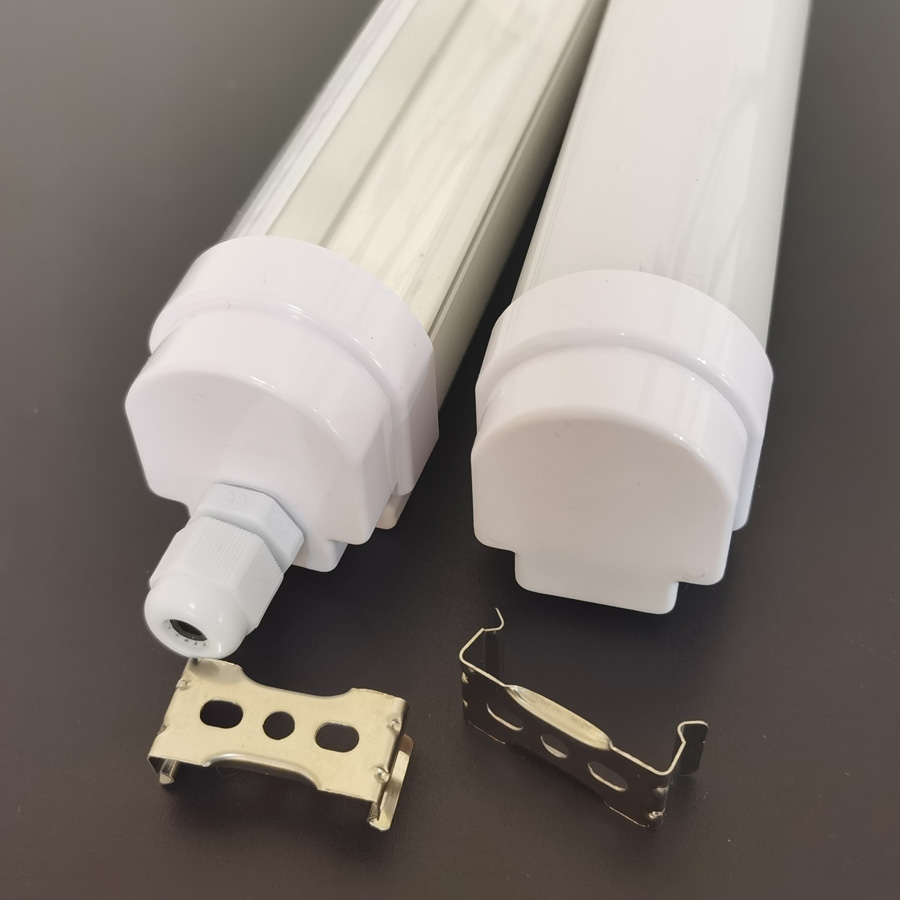

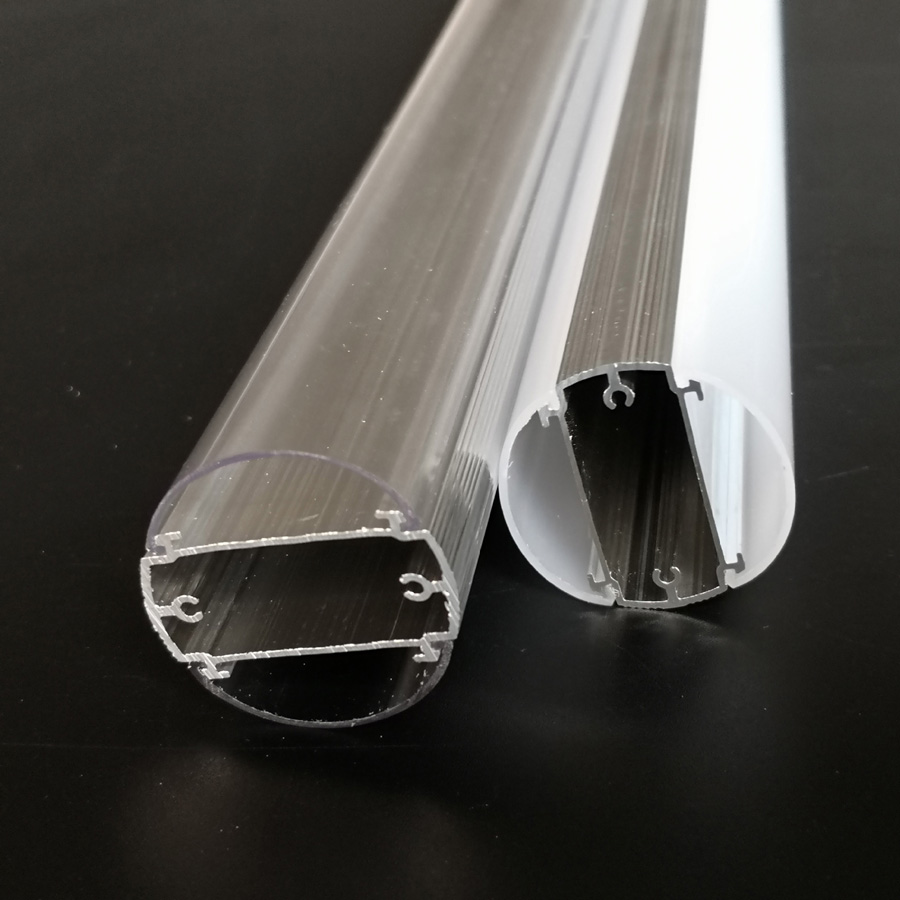

This is an LED waterproof batten light housing with a plastic tube diffuser on the outside and an aluminum profile radiator on the inside. This structure can double the waterproof effect. From the detailed pictures of the product below, you can see all the accessories of this product. The quality of these accessories has been confirmed by our company after repeated tests. From raw materials to final products, we are involved in every detail. From waterproof gaskets to waterproof nuts to breathing valves, we strive to ensure the best quality of this LED waterproof batten light housing.

Product Parameter (Specification)

| Item NO. | JE-605 |

| Length | 600mm customized |

| Tube | Tri-proof |

| Size | 600*83*68mm |

| PCB board size | 491*49*1mm |

| Driver | Internal |

| Max height of driver | 25mm |

| Aluminum material | 6063 aluminum alloy |

| Aluminum base color | Silver |

| Plastic diffuser material | Polycarbonate |

| Plastic diffuser color | Frosted, Clear(transparent) |

| End caps | Plastic |

| Waterproof | IP65 |

| Structural components |

1,Lampshade*1 2,Heat sink*1 3 ,PCB* 1 4 Gasket *4 5, Plug*4 6, M4*15 Phillips pan head tapping screw* 4 7,Terminal*1 8,PG13.5 waterproof connector*1 9,Waterproof vent valve*1 10,Rubber stopper*1 11,PCB size: 49*1.0mm 12,Driver Height <25mm 13,PC color: transparent/ diffuser |

Product Feature And Application

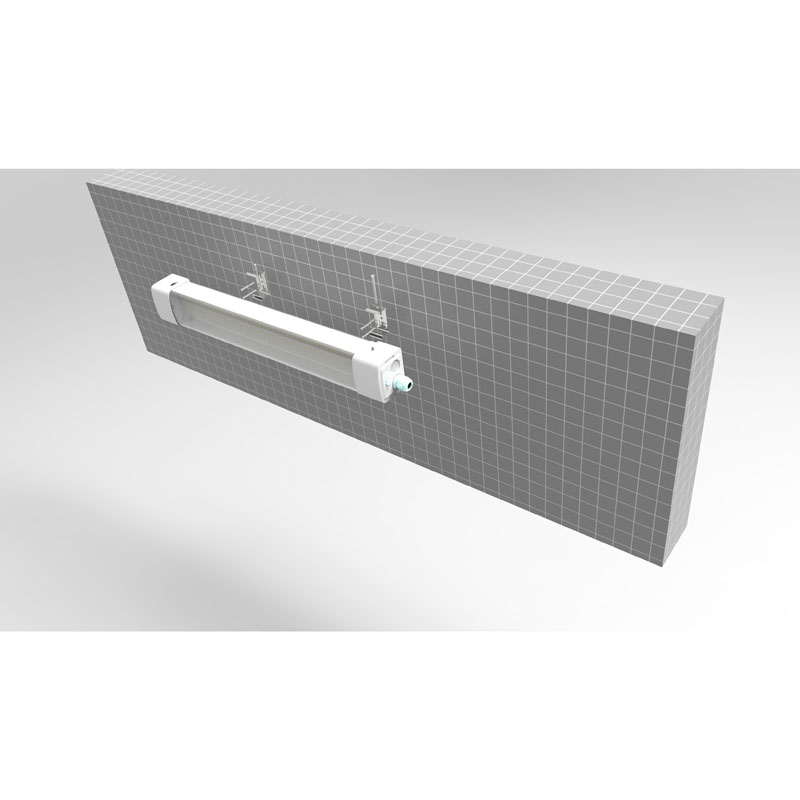

LED waterproof batten light housing can be made into many kinds of tri-proof lights, this lights are generally used in places with strong corrosive, dusty and rainy industrial lighting needs, such as power plants, steel, petrochemicals, ships, stadiums, parking lots, basements, etc.

Product Details

More details of this IP65 LED waterproof batten light housing:

Product Qualification

Dongguan Jinen Lighting Technology Co., Ltd. was established in 2017. It is a professional plastic and aluminum extrusion manufacturer integrating R&D, production and manufacturing. It has been rated as a high-tech enterprise in the industry. After 5 years of hard work, the company has nearly 100 employees, including 10 in the R&D department and 8 in the sales department. It has 20 plastic extrusion production lines, 5 aluminum extrusion production lines, 3 injection molding machines, and 5 precision mold manufacturing equipment. 2 sets of test equipment (integrating sphere and color evaluation cabinet).

Deliver,Shipping And Serving

FAQ

Q1. How many staff are in your factory?

Re: 50-80 staff in the production line. 8 staff in the sales team, 10 staff in R&D.

Q2. What are your normal processes for regular order?

Re: We are very suggest customers give the forecast for the next three month. This are our normal processes for regular order:

Receiving PO--Sales confirm PI with customer--Receiving 30% payment in advance--Sales assistant proceed production and confirms the exact LT--QC confirms the goods are ready for shipping--Receiving the balance payment--Arranging shipment--after sales service.

Q3. What is the process of OEM order?

Re: Receiving drawing--Project manage confirm all production details with customer--Receiving tool production PO--Sales assistant proceed tool production--QC confirm samples are ready for shipping--Project manage confirm products with customer about every details-- start the regular order.

Q4. Is the mold opening cost borne by the customer or your factory?

Re: Customer pay the cost first, after the quantity is more than 50000 meters for total order, the tool cost can be deducted in order.

Q5. How long is your lead time?

Re: For our regular items the lead time is about 3-5 days. For customized items, the lead time is about 25-35 days including tools making time.