- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

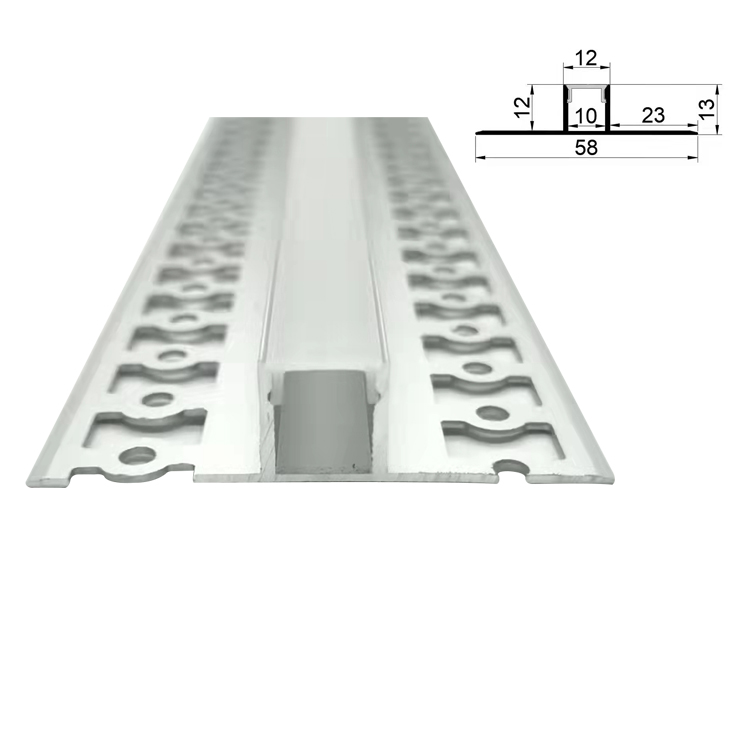

Recessed Linear LED Aluminum Profile

As a large-scale professional manufacturer of Recessed Linear LED Aluminum Profile for LED cabinet light accessories in China, JE has been doing its best to help and cooperate with the design, proofing and small batch trial production of LED cabinet light factories. This recessed linear LED aluminium profile is mainly used for LED strips up to 10mm wide. One of the most popular of our regular products, recessed profiles are an indispensable housing style in linear lighting projects. If you need professional LED aluminum profile solutions, please feel free to contact us.

Send Inquiry

JE is a high-tech enterprise integrating design, R&D and manufacturing in China. The main products are LED aluminum profiles, LED lamp housings, etc. The main advantage of this recessed linear LED aluminum profile is thin, and it is the most popular style that our company has recently launched. Because the old style requires a thicker aluminum groove to avoid light dot. But now the COB light strip has solved the problem of it. Therefore, using this LED aluminum channel not only saves the space for slotting, but also greatly improves the light efficiency of the line lamp.

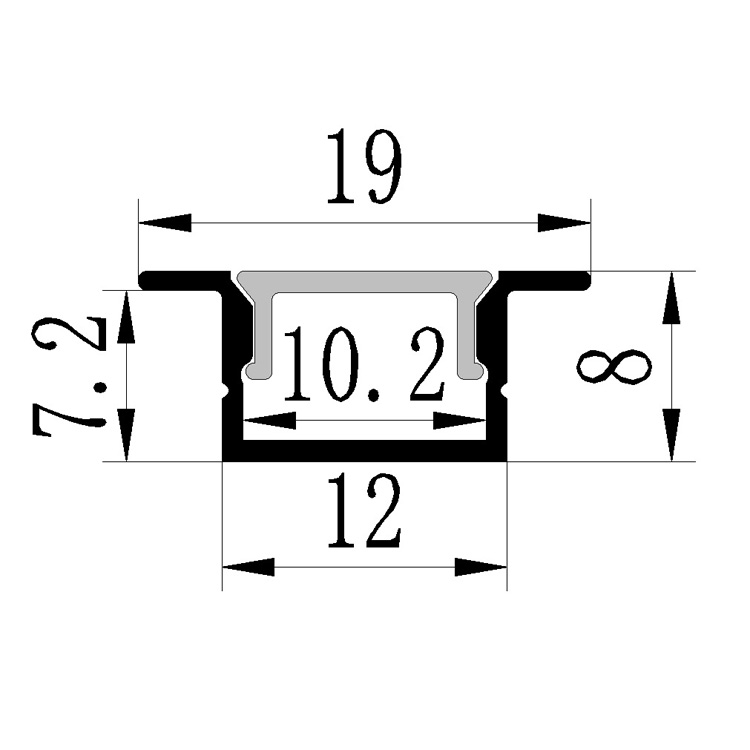

Recessed Linear LED Aluminum Profile Parameter (Specification)

|

Length |

1m, 2m, or cut-to-size |

|

Width |

12mm |

|

Height |

8mm |

|

Hole size |

13*8.2mm |

|

Max strip width |

10mm |

|

LED Aluminum profile |

6063-T5 aluminum alloy |

|

LED Aluminum profile color |

Silver and black |

|

LED plastic profile (Diffuser ) |

PC(Polycarbonate) |

|

LED plastic profile (Diffuser )color |

Frosted, or customize |

|

Mounted |

Recessed Mounted |

|

Clips |

Stainless steel |

|

End caps |

Plastic |

Recessed Linear LED Aluminum Profile Feature And Application

This recessed linear LED aluminum profile can be used in wardrobes, bedside tables, shoe cabinets, kitchen lockers and many other storage cabinets.

Recessed Linear LED Aluminum Profile Details

More details of this recessed LED aluminum profile:

Recessed Linear LED Aluminum Profile Qualification

As a professional manufacturer of LED aluminum profiles and LED plastic profiles, JE has 20 plastic extrusion machines and 5 aluminum extrusion machines, and has a professional integrating sphere to test whether the lamps manufactured by our lighting kit can meet the various requirements of customers. A variety of indicators, with professional standard light source testing equipment, used to detect the transmittance of plastic lampshade and other properties. From aluminum-plastic raw materials to extrusion production lines, from sample quality control to mass production control, from powerful perfect packaging to whole-hearted service, JE always focuses on product quality.

Deliver,Shipping And Serving

FAQ

Q1. What is process of OEM order?

Re: Receiving drawing--Project manage confirm all production details with customer--Receiving tool production PO--Sales assistant proceed tool production--QC confirm samples are ready for shipping--Project manage confirm products with customer about every details-- start the regular order.

Q2. How do you ensure quality?

Re: At first, we use new raw material all with environment protection certifications, please be sure we don’t use any re-product raw material.

Second, we have professional Quality Control department, both samples and finished products must be confirmed by QC before shipment.

Q3. How do you ensure leading time?

Re: We have professional Product Material Control(PMC) department, all orders are arranged by system.

Q4. Can you sell your products directly to engineers companies?

Re: Yes, and we can provide samples for each item, MOQ of each items for regular order is 1000 meters.

Q5. You have sales target finished amount requirement to the distributor?

Re: Yes, 1 million USD of annual order can become distributor in your country.