- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Strip Aluminum Profile

JE is a professional manufacturer of strip aluminum profiles, with more than 30 extrusion production lines and strong production strength.

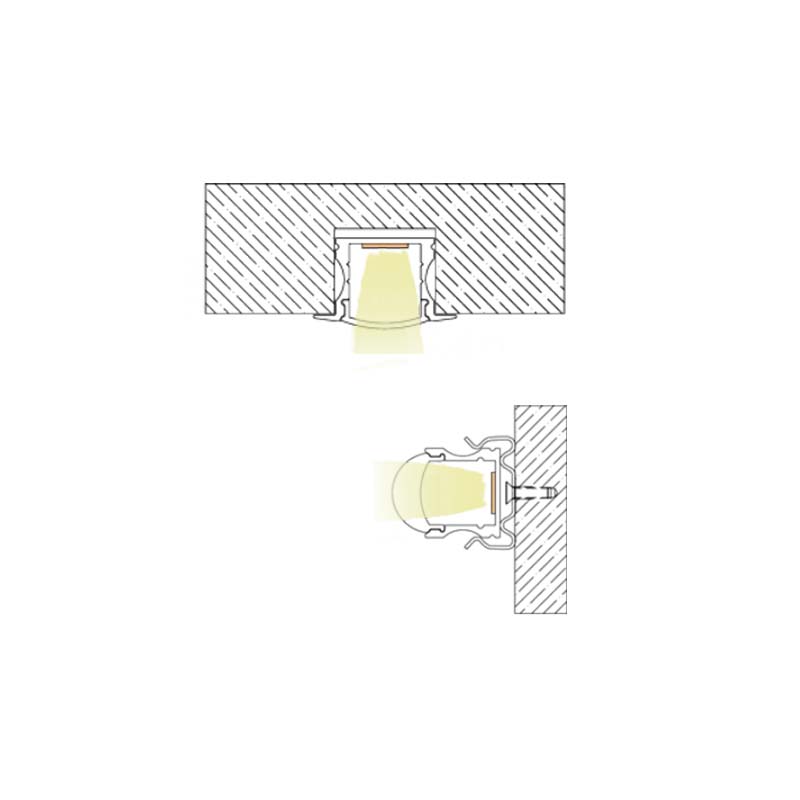

There are two installation methods for this strip aluminum profile:

The JE-88 version is for surface mounting with plastic plugs and stainless steel mounting clips.

The JE-89 style is for recessed mounting with plastic plugs.

As a professional LED profile aluminum and plastic factory, there are more than 500 types of male mold products, and OEM customized products are also welcome.

Send Inquiry

1. Products Introduction

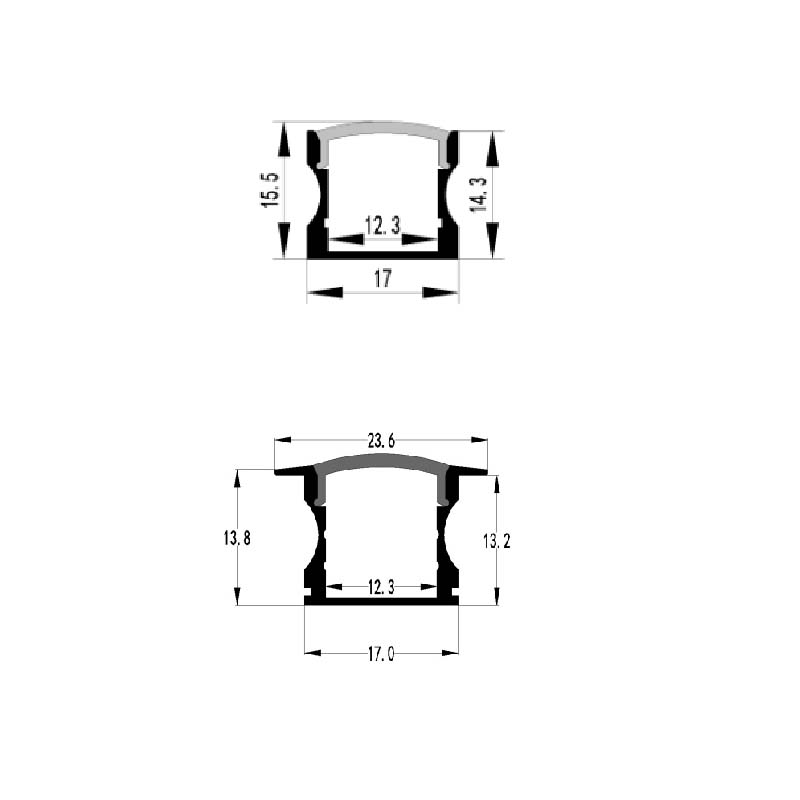

Strip aluminum profile has always been one of JE's main products, and it is also a product purchased by many large wholesalers. This strip aluminum profile is mainly used to install light bars with a width of 12mm. It is made of high-quality 6063-T5 aluminum material. The surface of the product produced is smooth and the heat dissipation effect is very good. The design of surface and recessed mounted installation can be matched with various occasions of lighting design. Therefore, the flexibility in the use of architectural linear lighting is very large.

2.Product Parameter (Specification)

|

Item NO. |

JE-88, JE-89 |

|

Length |

0.5-3m or customized |

|

Tube |

/ |

|

Diameter |

/ |

|

PCB board size |

12mm |

|

Driver |

/ |

|

Max height of driver |

/ |

|

Aluminum material |

6063 aluminum alloy |

|

Aluminum base color |

Silver/black |

|

Plastic cover material |

Polycarbonate |

|

Plastic cover color |

Frosted, Clear(transparent) |

|

End caps |

Plastic |

|

Waterproof |

IP20 |

|

Clips |

Stainless steel |

3.Product Feature And Application

This strip aluminum profile can be installed into cabinet and furniture pieces. Raw material is 6063 Aluminum alloy which is suitable for LED strips heating then increase the Eds lifetime. Raw material of diffuser is UV+-resistance, is available with frosted, semi-clear and clear(transparent).

4. Product Qualification

As a LED Aluminum Profile and LED plastic profile professional manufacturer, here are our main machines:

1.20 plastic extrusion machines,

2.5 aluminum extrusion machines,

3.3 of injection molding machines,

4.5 of precision mold manufacturing equipment,

5.A professional integrating sphere to test whether the lamps made by our lamp kit can meet the various indicators required by customers,

6.A professional standard light source testing equipment for testing the light transmittance and other properties of plastic lampshades.

JE always focus on product qualification from aluminum and plastic raw material to extrusion production line, from samples quality control to mass production control, from strong perfect package to whole-heart service.

5. Deliver,Shipping And Serving