- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

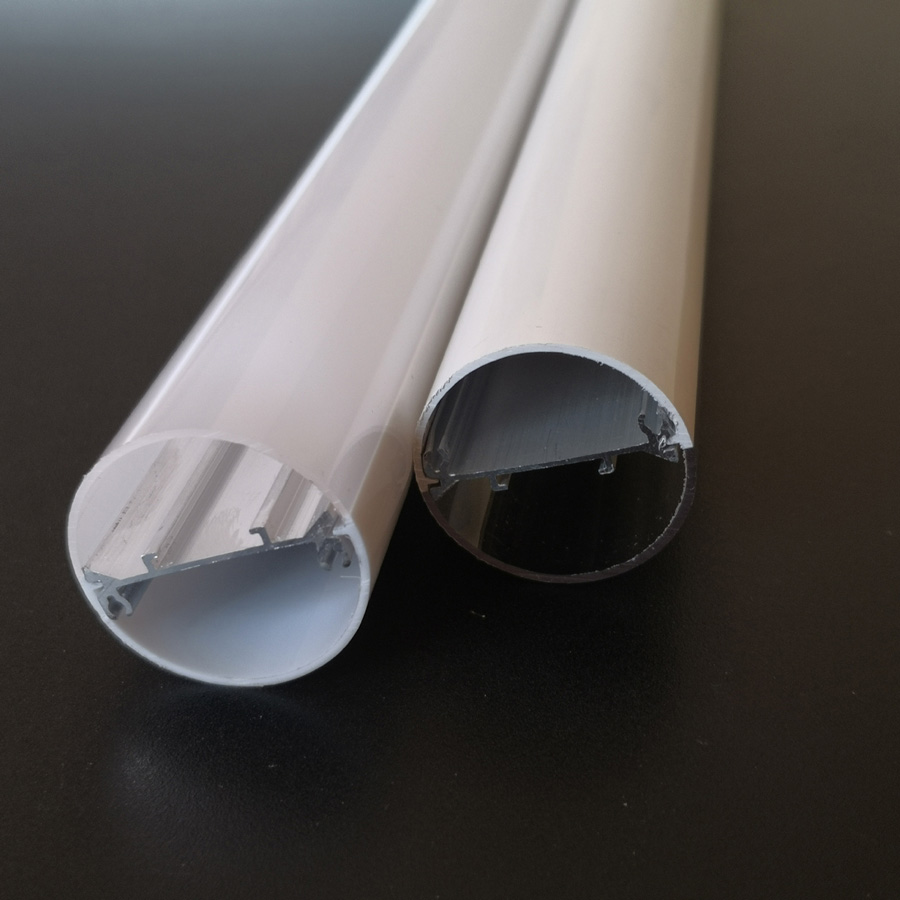

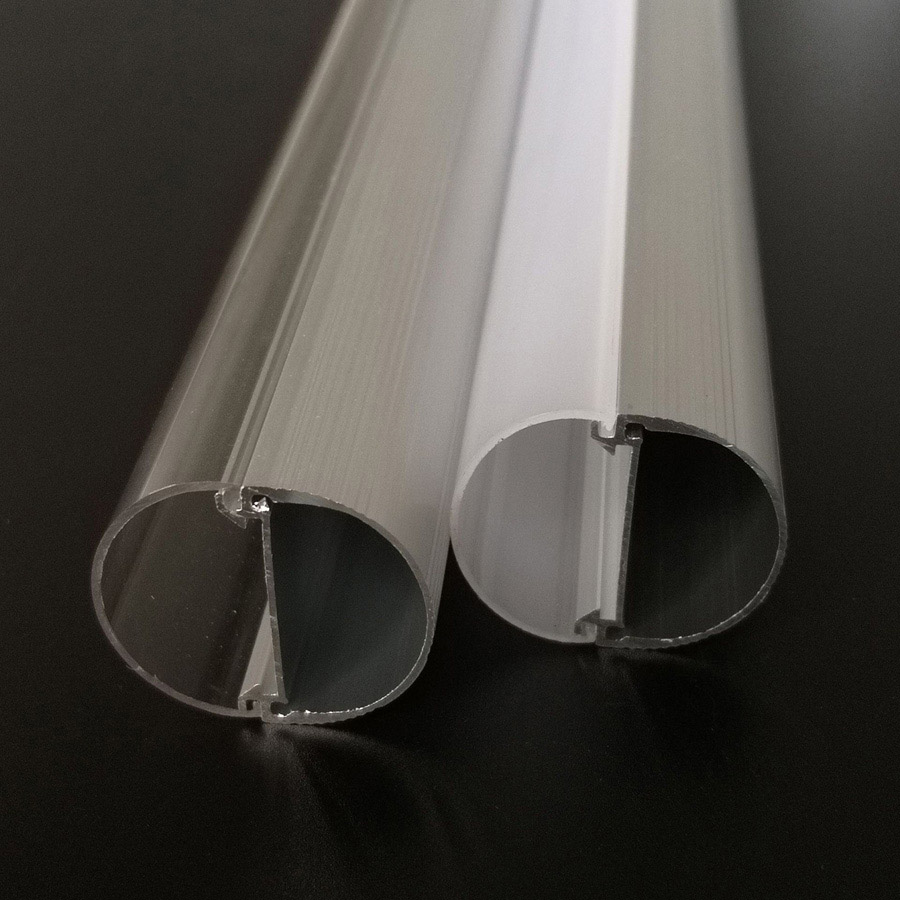

T8 LED Tube Housing

JE has hundreds of T8 LED tube housings and is a professional manufacturer of linear lighting housings in China. T8 LED tube housing is JE’s main product, there are mainly two styles, one is the lower part is aluminum, the upper part is PC diffuser; One is that the entire lamp tube is made of plastic on the outside, and aluminum profiles are inserted inside, or it can be directly inserted into the PCB board. These two styles have their own advantages, so customers can choose the most suitable style according to the requirements of the project. For more information, please feel free to consult.

Send Inquiry

1. Products Introduction

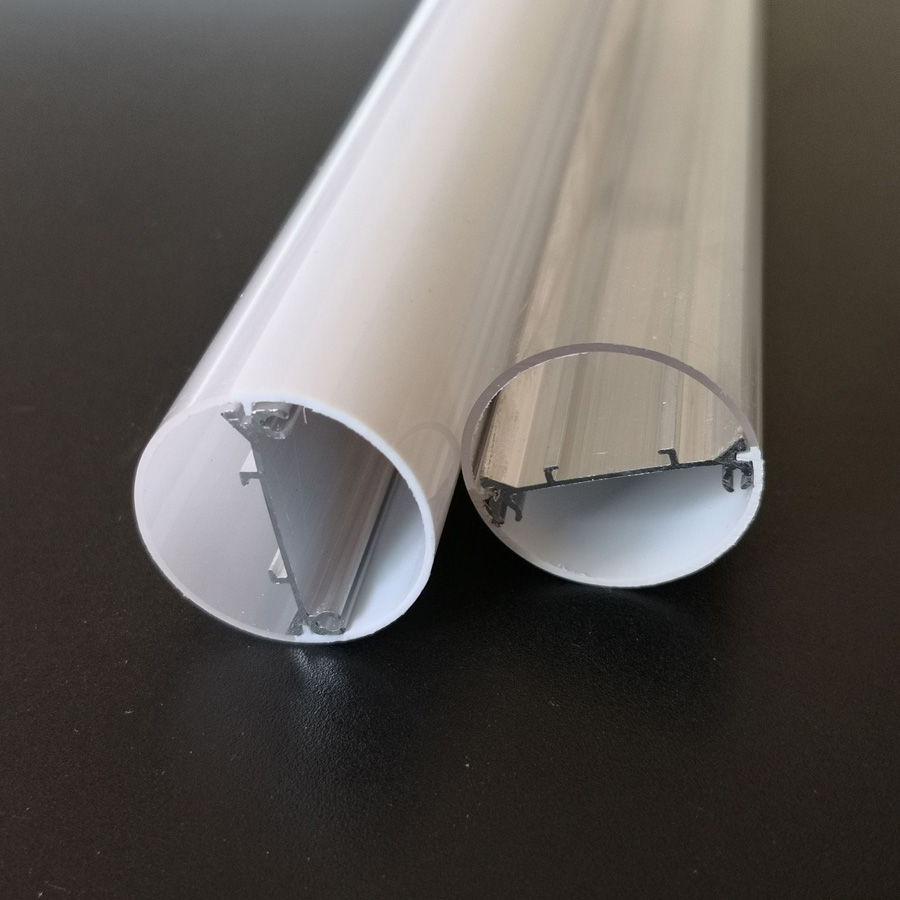

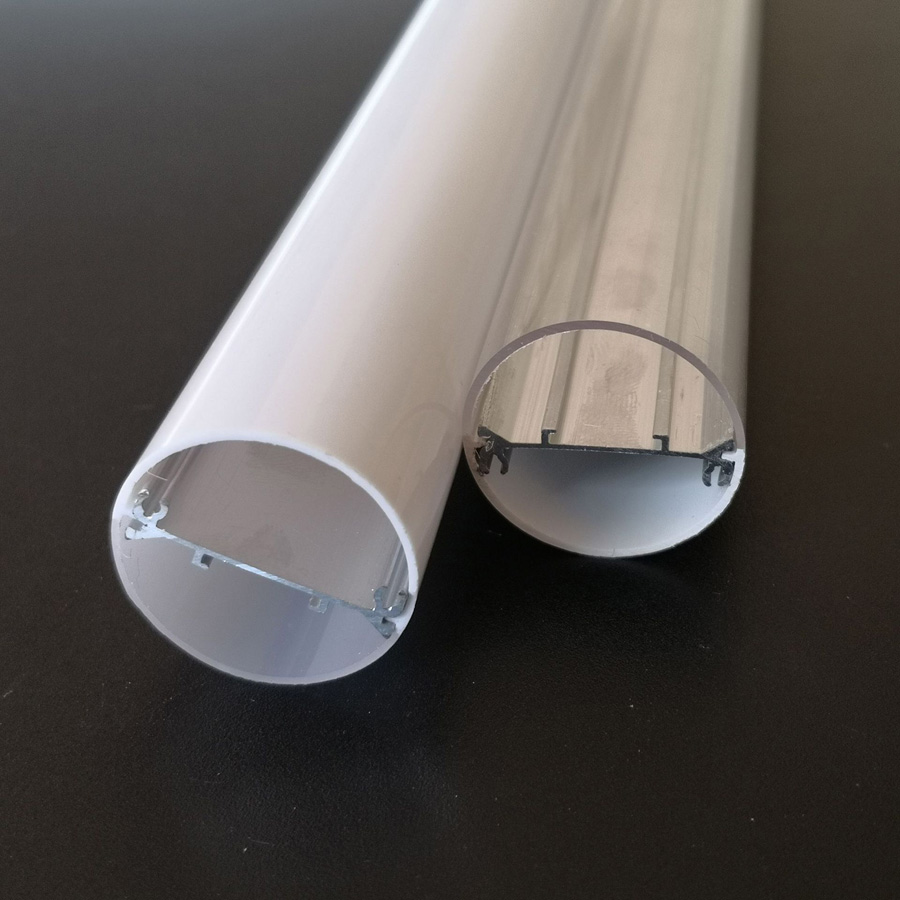

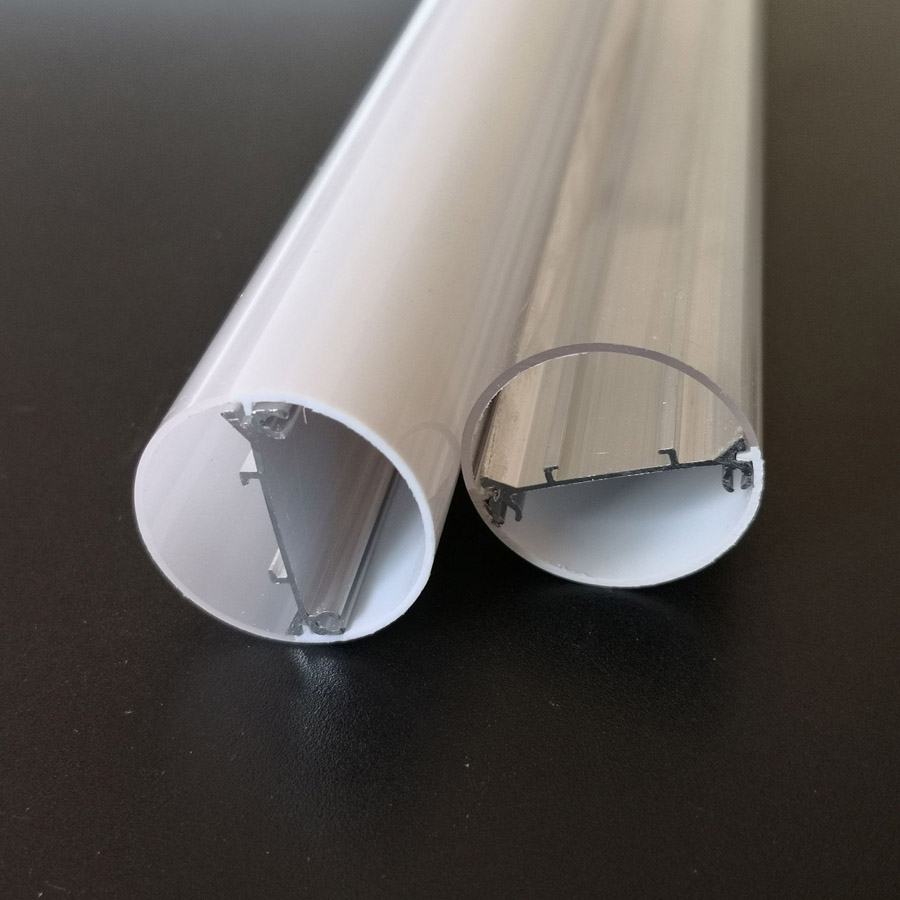

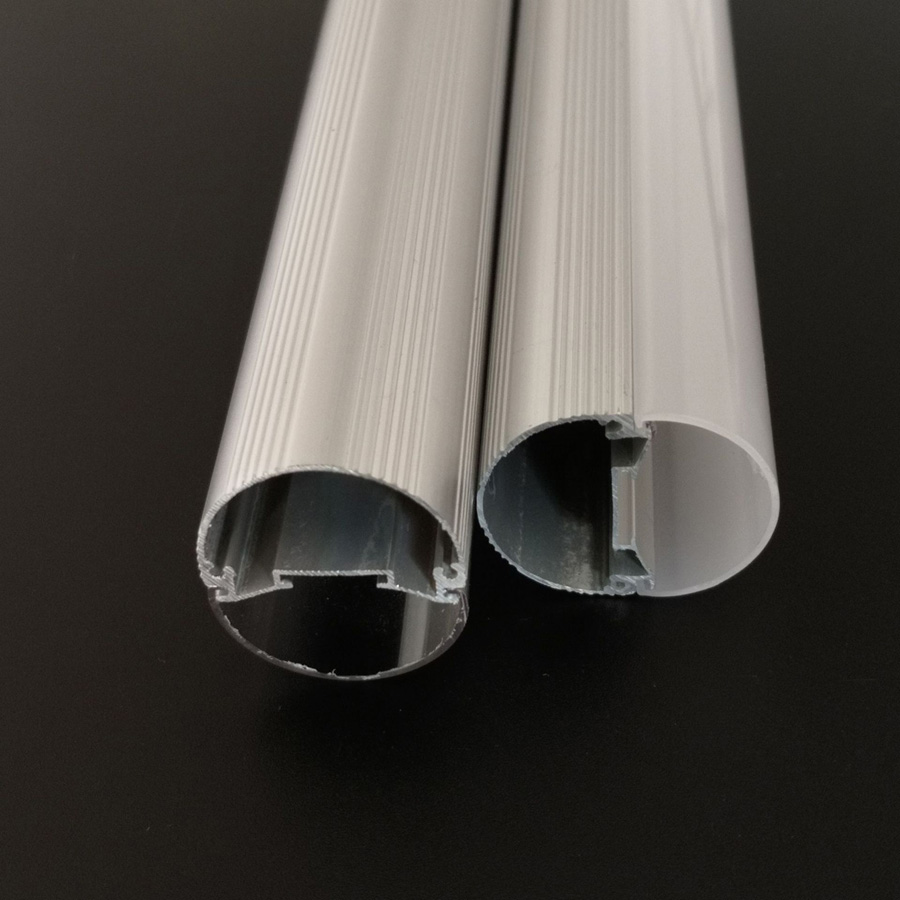

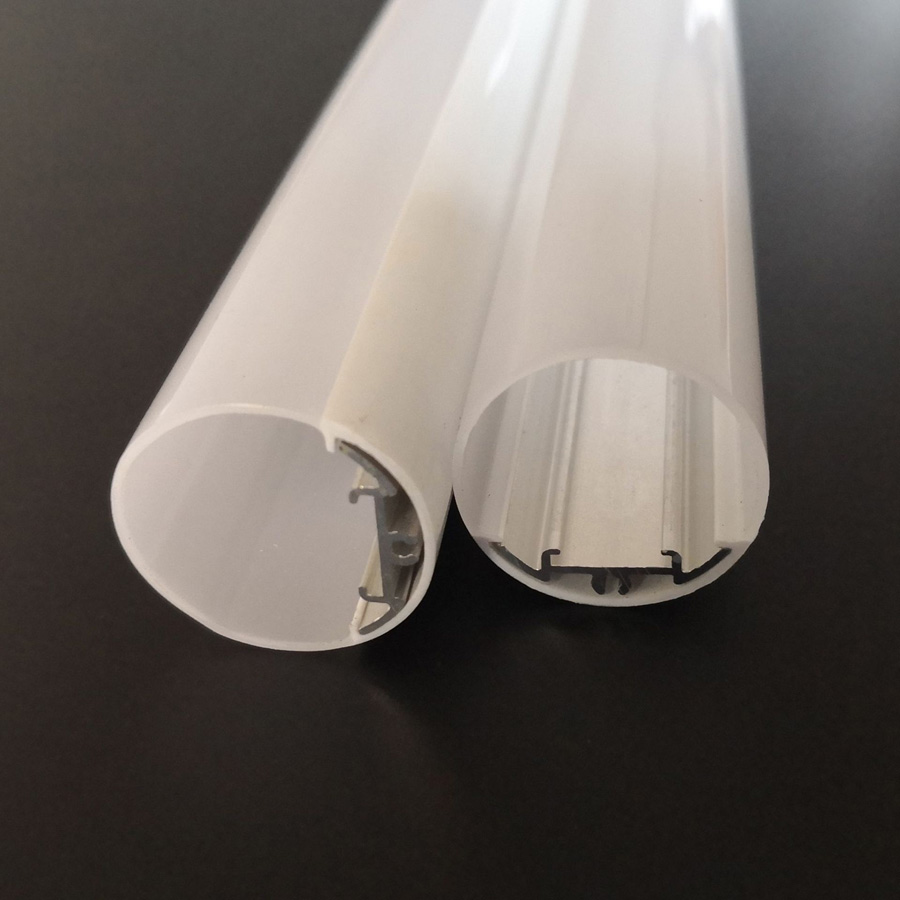

JE is a professional manufacturer of T8 LED tube housing solutions in China. The shell of this T8 LED tube housing is an all-plastic tube + insert aluminum profile structure. The advantage of this style is that the cost is low, and it can be made into two styles of non-waterproof and waterproof, so many customers use this male mold product design plant lighting. This saves the time and cost of reopening the mold. The PCB board width of this T8LED lamp housing also has two options, 10mm and 12mm.

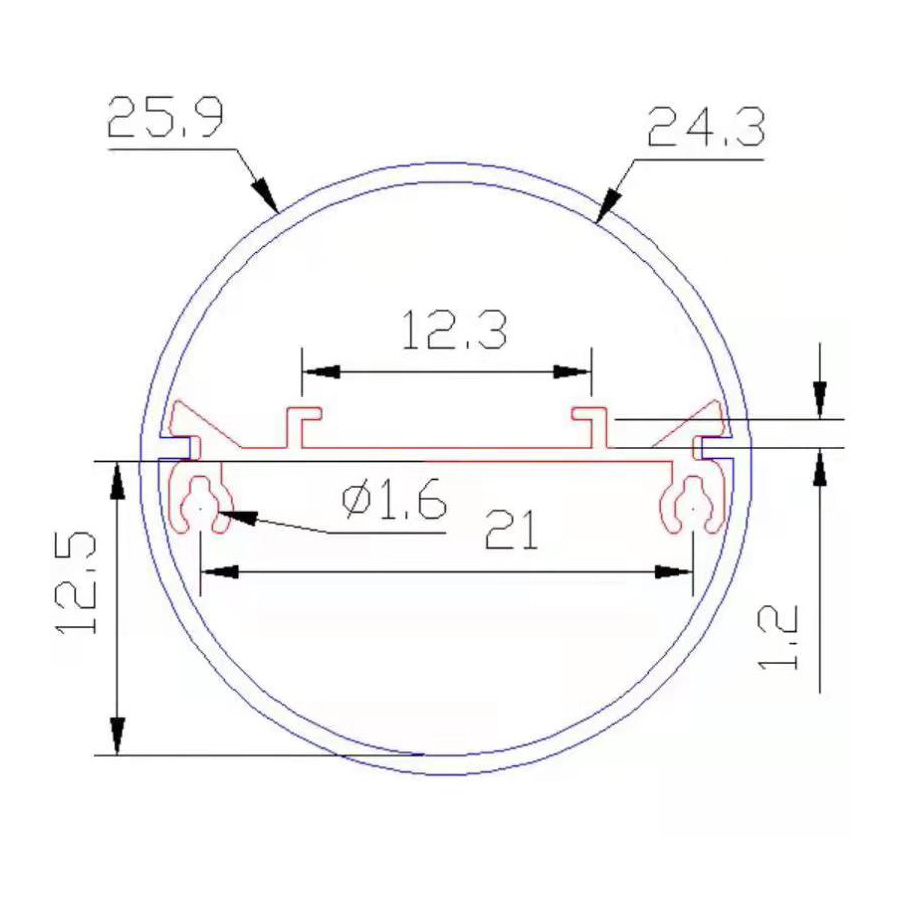

2.Product Parameter (Specification)

|

Length |

600mm, 900mm, 1200mm, 1500mm, 2400mm or customized |

|

Tube |

T8 |

|

Diameter |

26mm |

|

PCB board size |

10*1mm/12*1mm |

|

Driver |

Internal |

|

Max height of driver |

12mm |

|

Aluminum profile inside material |

6063 aluminum alloy |

|

Aluminum profile inside color |

Silver |

|

Plastic tube material |

Polycarbonate |

|

Plastic tube color |

White base, Frosted and Clear(transparent) cover |

|

End caps |

Plastic(screwing and gluing) |

|

Waterproof |

IP20 or IP65 |

3.Product Feature And Application

This T8 LED tube housing is mainly used for home lighting, shopping mall lighting, school lighting, parking lot lighting, and more.

4. Product Details

More details of this T8 LED tube housing:

5. Product Qualification

As a professional manufacturer of LED aluminum profiles and LED plastic profiles, JE has 20 plastic extrusion lines and 5 aluminum extrusion lines, and has a professional integrating sphere to test whether the lamps manufactured by our lighting kits can meet the various requirements of customers. a requirement. Require. Require. Require. Indicators, equipped with professional standard light source testing equipment, used to test the light transmittance and other properties of plastic lampshades. From aluminum plastic raw materials to extrusion production lines, from sample quality control to mass production control, from powerful perfect packaging to wholehearted service, JE always focuses on product quality.

6. Deliver,Shipping And Serving

7.FAQ

Q1. Can you sell your products directly to engineering companies?

Re: Yes, and we can provide samples for each item, MOQ of each item for regular order is 1000 meters.

Q2. Do you have any products for LED tubes?

Re: Yes, we have LED tube housing for LED T6/T8/T10/T12 tube housing.

Q3. Can I cut the aluminium LED profile?

Re: Yes, it's only aluminium so a simple chop saw with suitable metal blade is the best for a clean cut, or even a hacksaw if doing it by hand.

Q4. Will the product deform during transportation?

Re: No, please be sure of our professional package.

Q5. What is process of OEM order?

Re: Receiving drawing--Project manage confirm all production details with customer--Receiving tool production PO--Sales assistant proceed tool production--QC confirm samples are ready for shipping--Project manage confirm products with customer about every details-- start the regular order..