- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

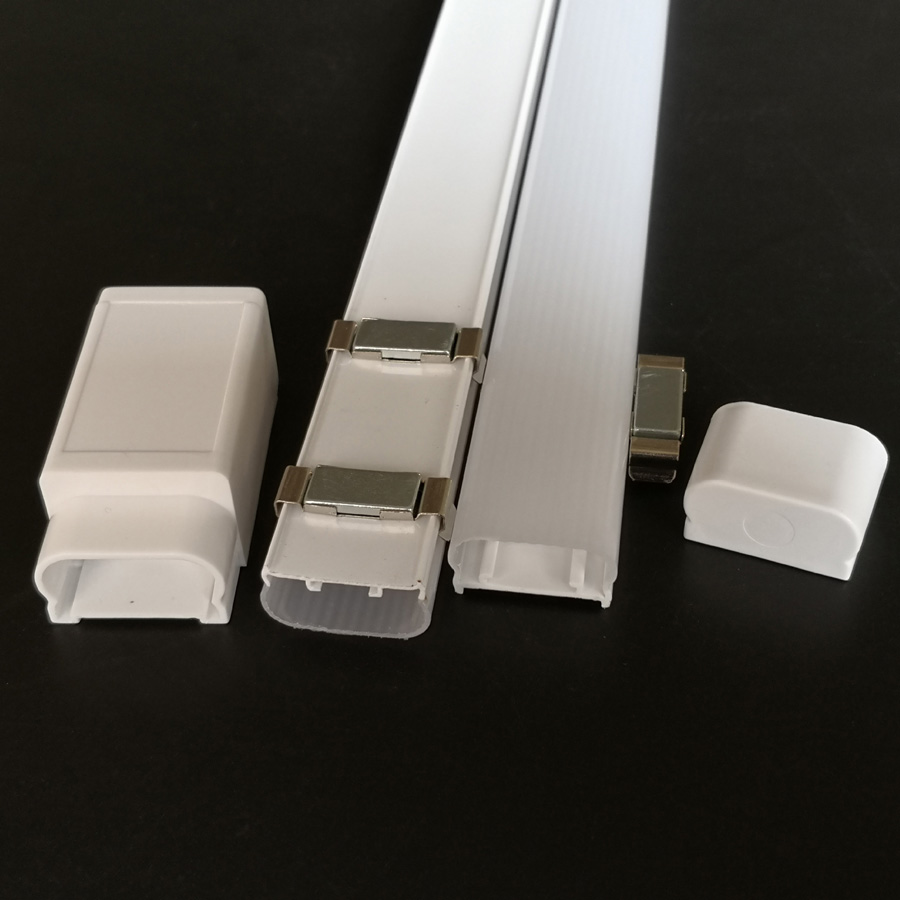

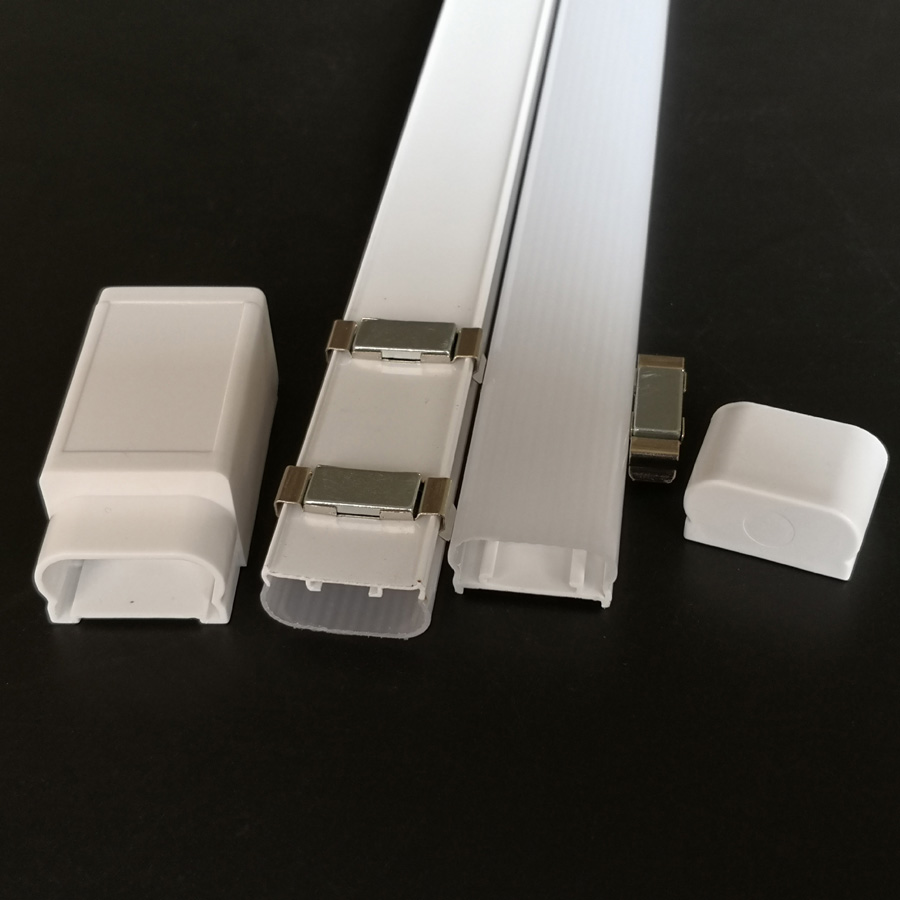

Customized Plastic Diffuser for Refrigerator and Freezer Light Housing

Established in 2017, JE factory mainly designs and develops LED plastic diffusers for LED lighting. With 5 years of production experience, it specializes in providing customers with various LED linear light diffuser solutions. It is a high-quality LED plastic diffuser manufacturer. business. This customized plastic diffuser for refrigerator and freezer light housing is suitable for PCB boards with a board width of 10mm. If you have drawings that need to be customized, please contact us as soon as possible.

Send Inquiry

1. Products Introduction

JE’s customized plastic diffuser is not only used for refrigerator and freezer lights, but also can be used for plant lights. The raw materials of this JE-39 customized plastic diffuser for refrigerator and freezer light housing are made of high-quality plastics that can resist UV, and the flame retardant can reach various flame retardant grades as required.

This product has high light transmittance, good flame retardant effect, wear-resistant and durable, multi-functional, and long life. One is that the lamp itself does not Contains any harmful chemical components (such as Hg, etc.). The second is energy saving. LED fluorescent lamps are more energy-saving and environmentally friendly than traditional fluorescent lamps. It has the following advantages:●Excellent physical and mechanical properties, especially excellent impact resistance, high tensile strength, flexural strength and compressive strength; small creep and stable size;

●It has good heat resistance and low temperature resistance, and has stable mechanical properties, dimensional stability, electrical properties and flame retardancy in a wide temperature range; Low water absorption, small shrinkage, high dimensional accuracy, good dimensional stability, low air permeability of the film, and it is a self-extinguishing material;

●Resistant to oil, acid, strong alkali, oxidizing acid, amine and ketone, soluble in chlorinated hydrocarbons and aromatic solvents.

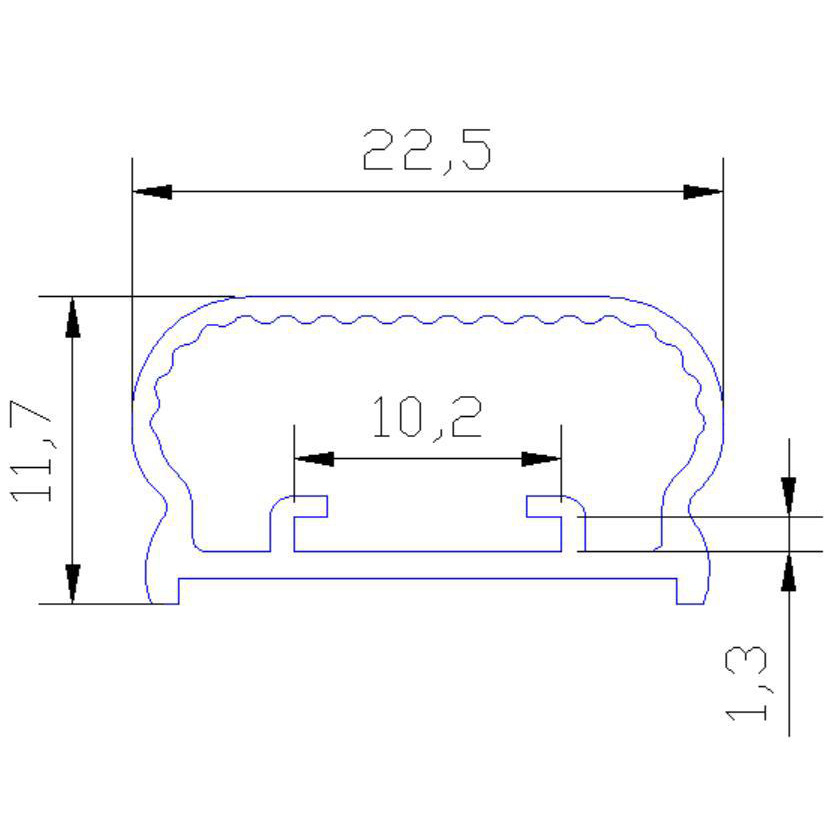

2.Product Parameter (Specification)

|

Item NO. |

JE-39 |

|

Length |

600mm, 900mm, 1200mm, 1500mm, 2400mm or customized |

|

Tube |

/ |

|

Diameter |

/ |

|

PCB board size |

10*1.0mm |

|

Driver |

Put into end caps |

|

Max height of driver |

/ |

|

Aluminum base material |

/ |

|

Aluminum base color |

/ |

|

Plastic tube material |

Polycarbonate |

|

Plastic tube color |

Frosted, Clear(transparent) |

|

End caps |

Plastic |

|

Waterproof |

IP65 |

3.Product Feature And Application

This JE-39 customized plastic diffuser for refrigerator and freezer light housing is widely used in refrigerator, freezer, cold storage, super market and so on.

4. Product Details

More details of this JE-38 plastic extrusion for refrigerator and freezer light fixtures:

5. Product Qualification

As a LED Aluminum Profile and LED plastic profile professional manufacturer, here are our main machines:

1.20 plastic extrusion machines,

2.5 aluminum extrusion machines,

3.3 of injection molding machines,

4.5 of precision mold manufacturing equipment,

5.A professional integrating sphere to test whether the lamps made by our lamp kit can meet the various indicators required by customers,

6.A professional standard light source testing equipment for testing the light transmittance and other properties of plastic lampshades.

JE always focus on product qualification from aluminum and plastic raw material to extrusion production line, from samples quality control to mass production control, from strong perfect package to whole-heart service.

6. Deliver,Shipping And Serving

7.FAQ

Q1. Where is your factory located?

Re: We are located “World manufacturer” Dongguan city, Guangdong province, China.

Q2. How many machines in your factory?

Re: 20 of plastic extrusion production lines,

5 of aluminum extrusion production lines,

3 of injection molding machines,

5 of precision mold manufacturing equipments,

2 of test equipment(integrating sphere and Color Assessment Cabinet).

Q3. What is your normal processes for regular order?

Re: We are very suggest customer give the forecast for the next three month. This are our normal processes for regular order:

Receiving PO--Sales confirm PI with customer--Receiving 30% payment in advance--Sales assistant proceed production and confirm the exact LT--QC confirm the goods are ready for shipping--Receiving the balance payment--Arranging shipment--after sales service.

Q4. Do your LED profiles be easy to install?

Re: Yes, We provide complete installation accessories.

Q5. What raw material do you use for LED plastic profiles?

Re: Polycarbonate, PMMA and ABS.