- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

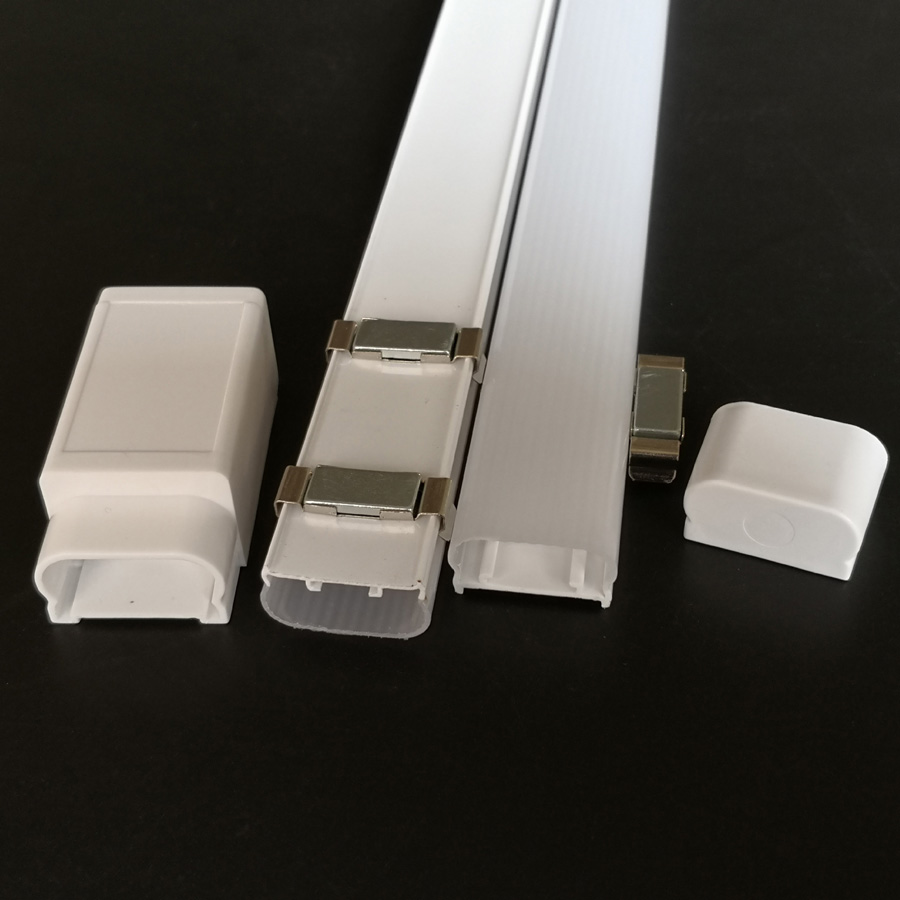

Plastic Extrusion for Refrigerator and Freezer Light Fixtures

JE owns 20 plastic extruders, as an excellent OEM&ODM LED plastic extrusion manufacturer supplier in China, specializing in extruding LED plastic profiles for LED lighting. This plastic extrusion for refrigerator and freezer light fixtures is suitable for PCB boards with a board width of 12mm. The plastic profiles produced by our company are recognized and trusted by the majority of LED lighting factories with high quality, reasonable price and diversified styles. Our company sincerely hopes to cooperate with you.

Send Inquiry

1. Products Introduction

Plastic extrusion profile is a very mature product of JE, and it is also a product with a very large amount of purchases at home and abroadThe raw materials of this JE-38 plastic extrusion for refrigerator and freezer light fixtures are made of high-quality plastics that can resist UV, and the flame retardant can reach various flame retardant grades as required.

The light transmittance of the lampshade is 85-95%, and some can reach more than 97%.Transparent lampshade features: high light transmittance, no stretch marks, no colorful lines.

Milky white lampshade features: no light spots, no dark areas, no lamp beads.

2.Product Parameter (Specification)

|

Item NO. |

JE-38 |

|

Length |

600mm, 900mm, 1200mm, 1500mm, 2400mm or customized |

|

Tube |

/ |

|

Diameter |

/ |

|

PCB board size |

12*1.0mm |

|

Driver |

Put into end caps |

|

Max height of driver |

/ |

|

Aluminum base material |

/ |

|

Aluminum base color |

/ |

|

Plastic tube material |

Polycarbonate |

|

Plastic tube color |

Frosted, Clear(transparent) |

|

End caps |

Plastic |

|

Waterproof |

IP65 |

3.Product Feature And Application

This JE-38 plastic extrusion for refrigerator and freezer light fixtures is widely used in refrigerator, freezer, cold storage, super market and so on.

4. Product Details

More details of this JE-38 plastic extrusion for refrigerator and freezer light fixtures:

5. Product Qualification

As a LED Aluminum Profile and LED plastic profile professional manufacturer, here are our main machines:

1.20 plastic extrusion machines,

2.5 aluminum extrusion machines,

3.3 of injection molding machines,

4.5 of precision mold manufacturing equipment,

5.A professional integrating sphere to test whether the lamps made by our lamp kit can meet the various indicators required by customers,

6.A professional standard light source testing equipment for testing the light transmittance and other properties of plastic lampshades.

JE always focus on product qualification from aluminum and plastic raw material to extrusion production line, from samples quality control to mass production control, from strong perfect package to whole-heart service.

6. Deliver,Shipping And Serving

7.FAQ

Q1. Where is your factory located?

Re: We are located “World manufacturer” Dongguan city, Guangdong province, China.

Q2. Is the mold opening cost borne by the customer or your factory?

Re: Customer pay the cost first, after the quantity is more than 50000 meters for total order, the tool cost can be deducted in order.

Q3. How many days is the tool production of LED aluminum and plastic profile?

Re: Usually 7-15 days.

Q4. Can Your products be installed under the cold weather?

Re: Yes, Weather resistance of PC is -40 degree to 120 degree.

Q5. What is process of OEM order?

Re: Receiving drawing--Project manage confirm all production details with customer--Receiving tool production PO--Sales assistant proceed tool production--QC confirm samples are ready for shipping--Project manage confirm products with customer about every details-- start the regular order.