- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

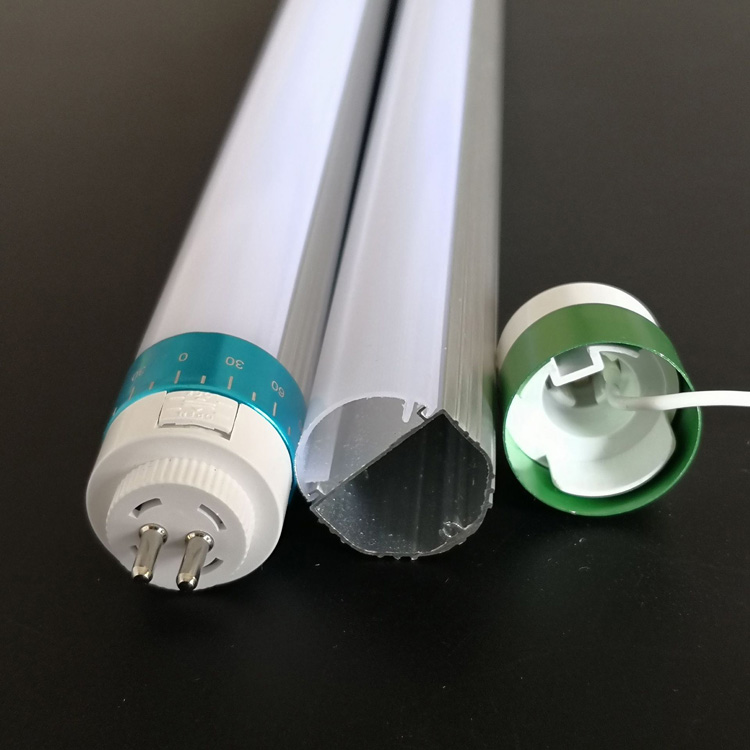

LED T5 Housing

As a professional LED tube housing manufacturer, in addition to LED T5 housing, JE's conventional products include LED T6 housing, LED T8 housing, LED T10 housing and LED T12 housing, and can also provide a variety of LED tri-proof tube housing, and can also provide customers with Customized service. LED T5 housing is our very popular regular product series, many linear lighting used in trains and subways will use T5 series because of its small size and beautiful appearance. And some special spaces just need T5 lighting is enough, which is both environmentally friendly and energy-saving.

Send Inquiry

1. Products Introduction

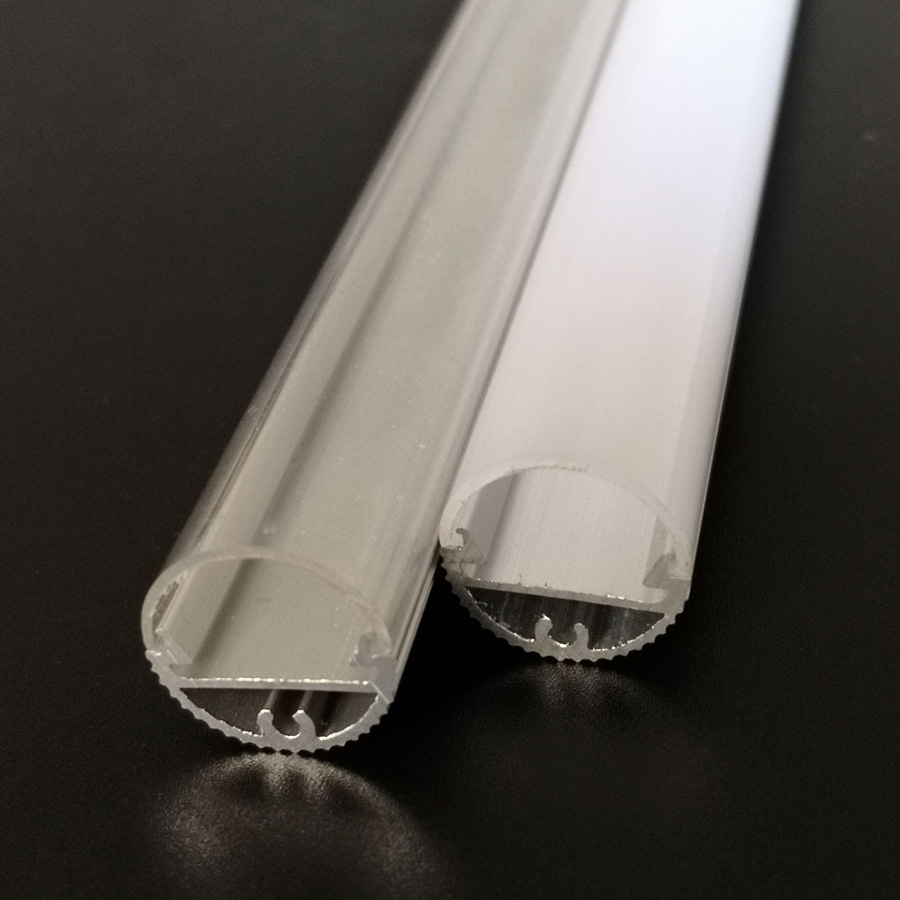

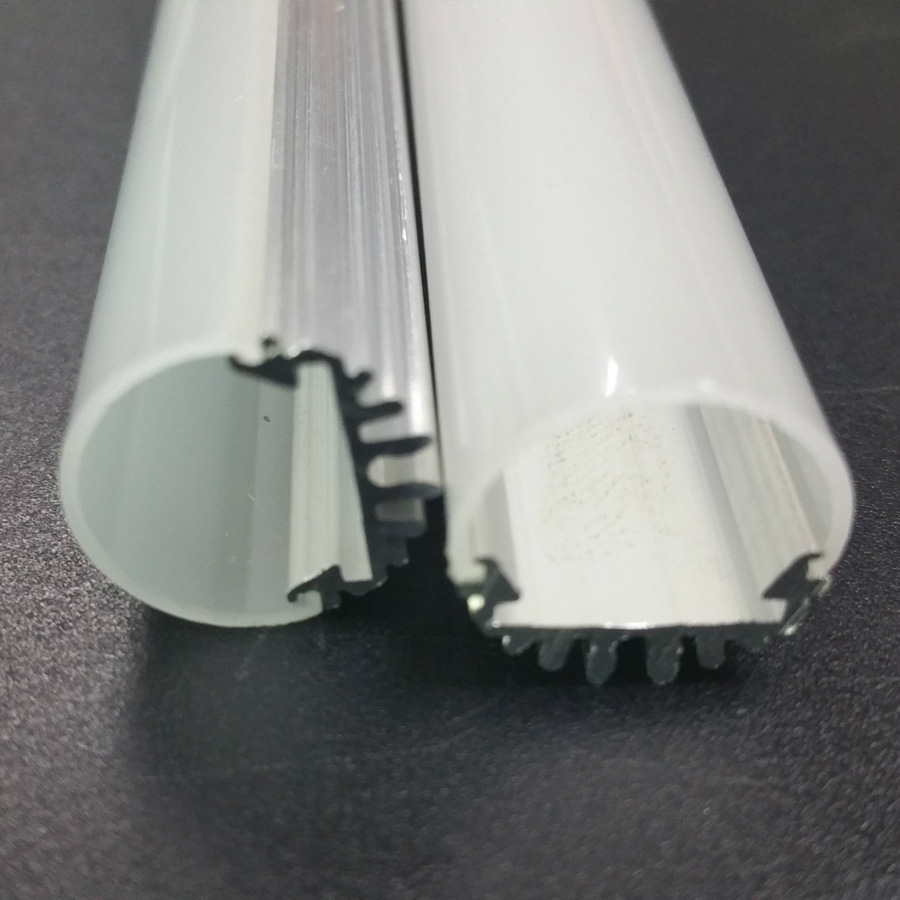

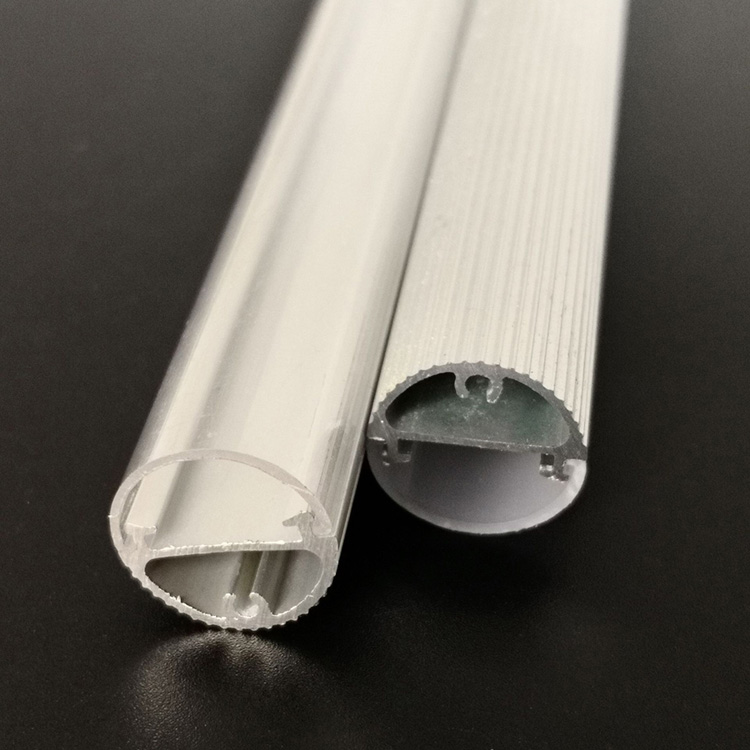

JE's T5 housings are very popular, and they are supplied to many manufacturers specializing in the production of LED T5 tubes with very excellent response. The shell of this LED T5 housing is a half-aluminum and half-plastic structure. The bottom aluminum profile is made of high-quality 6063 raw materials, which is a material that is very suitable for LED lamp beads to dissipate heat. After being formed by our mature extrusion process, the surface has no scratches. . The PC diffuser is made of high-quality polycarbonate, the transparency of the transparent cover is above 96%, and the surface has no water marks and impurities.

2.Product Parameter (Specification)

|

Length |

600mm, 900mm, 1200mm, 1500mm, 2400mm or customized |

|

Tube |

T5 |

|

Diameter |

15mm |

|

PCB board size |

10*1mm |

|

Driver |

External or put in end caps |

|

Aluminum tube material |

6063-T5 aluminum alloy |

|

Aluminum tube color |

Silver |

|

Plastic cover material |

Polycarbonate |

|

Plastic cover color |

Frosted, Clear(transparent) or stripe. |

|

End caps |

Plastic |

3.Product Feature And Application

This LED T5 housing is the main style of T5 lamps, mainly used in shopping malls, parking lots, hospitals, schools and other public places.

4. Product Details

More details of this LED T5 housing:

5. Product Qualification

As a LED Aluminum Profile and LED plastic profile professional manufacturer, here are our main machines:

1.20 plastic extrusion machines

2.5 aluminum extrusion machines,

3.A professional integrating sphere to test whether the lamps made by our lamp kit can meet the various indicators required by customers,

4.A professional standard light source testing equipment for testing the light transmittance and other properties of plastic lampshades.

JE always focus on product qualification from aluminum and plastic raw material to extrusion production line, from samples quality control to mass production control, from strong perfect package to whole-heart service.

6. Deliver,Shipping And Serving

7.FAQ

Q1. Do you provide sample? Free or charge?

Re: Yes, we charge for samples.

Q2. What is your term of payment?

Re: 30% payment in advance, the balance will be paid before shipment.

Q3. How many staff are in your factory?

Re: 50-80 staff in the production line. 8 staff in the sales team, 10 staff in R&D.

Q4. How many machines are there in your factory?

Re: 20 of plastic extrusion production lines,

5 of aluminum extrusion production lines,

3 of injection molding machines,

5 of precision mold manufacturing equipments,

2 of test equipment(integrating sphere and Color Assessment Cabinet).

Q5. What is your normal processes for regular order?

Re: We are very suggest customer give the forecast for the next three month. This are our normal processes for regular order:

Receiving PO--Sales confirm PI with customer--Receiving 30% payment in advance--Sales assistant proceed production and confirm the exact LT--QC confirm the goods are ready for shipping--Receiving the balance payment--Arranging shipment--after sales service.