- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

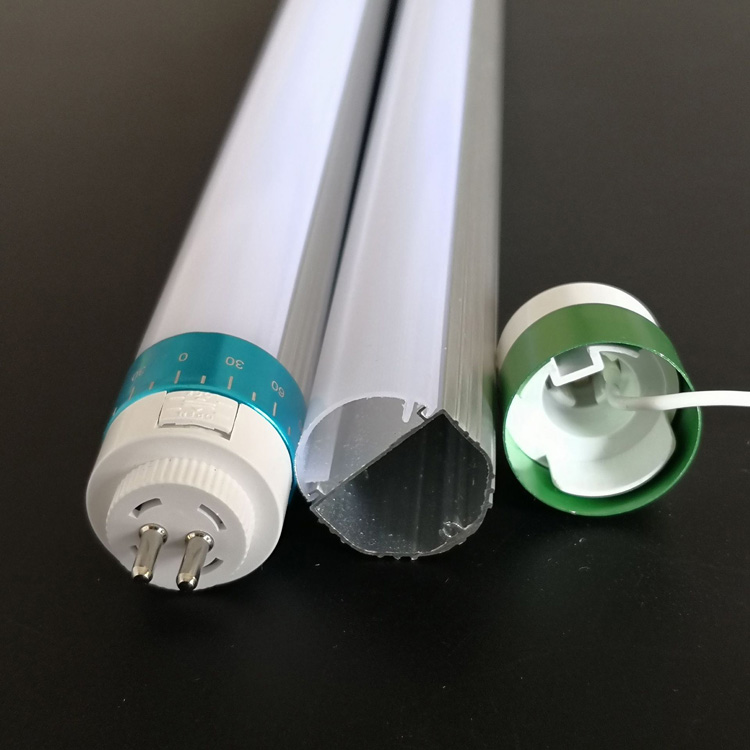

T5 Housing

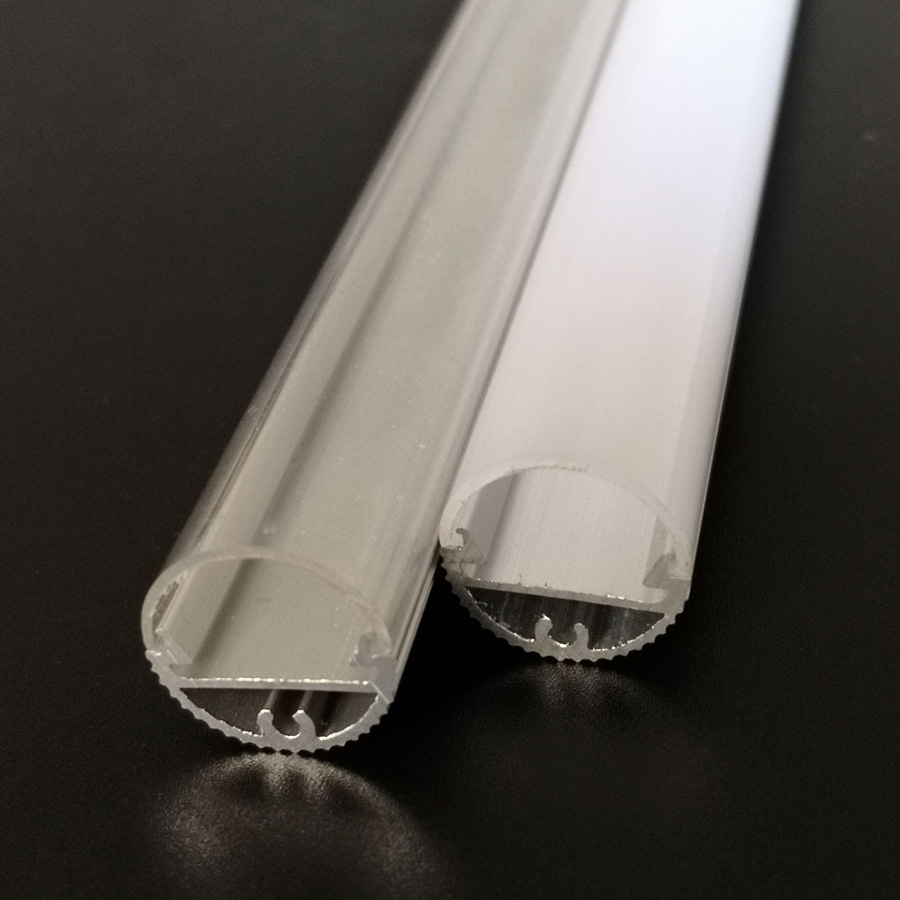

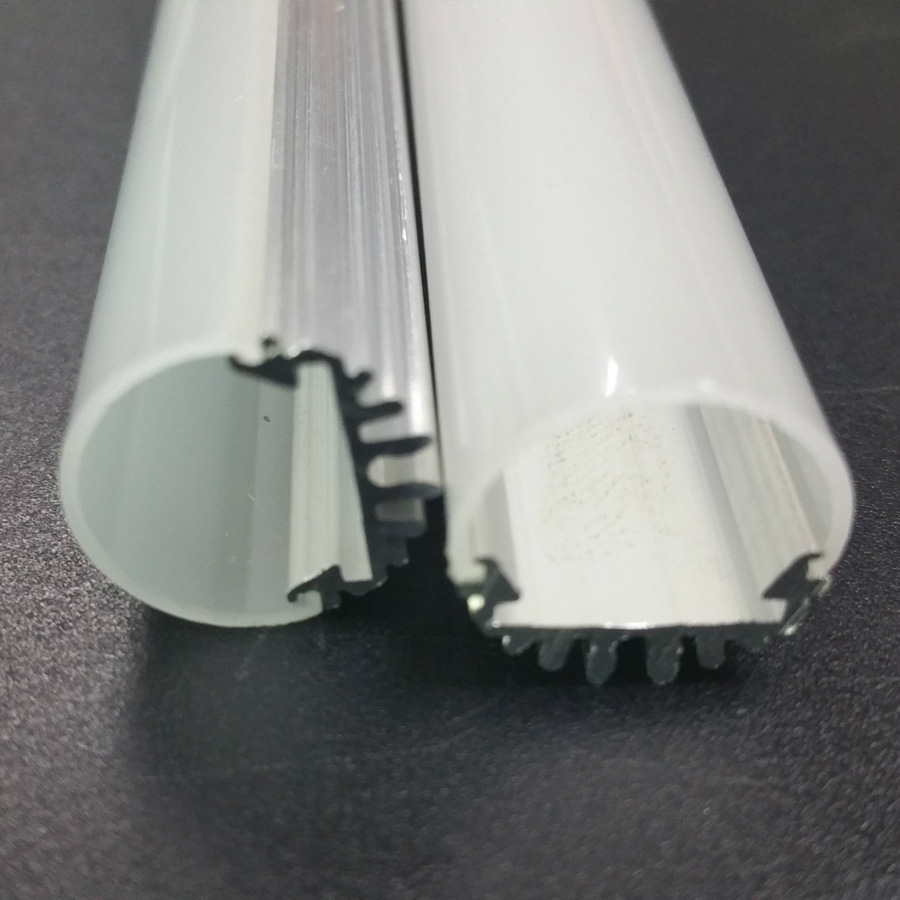

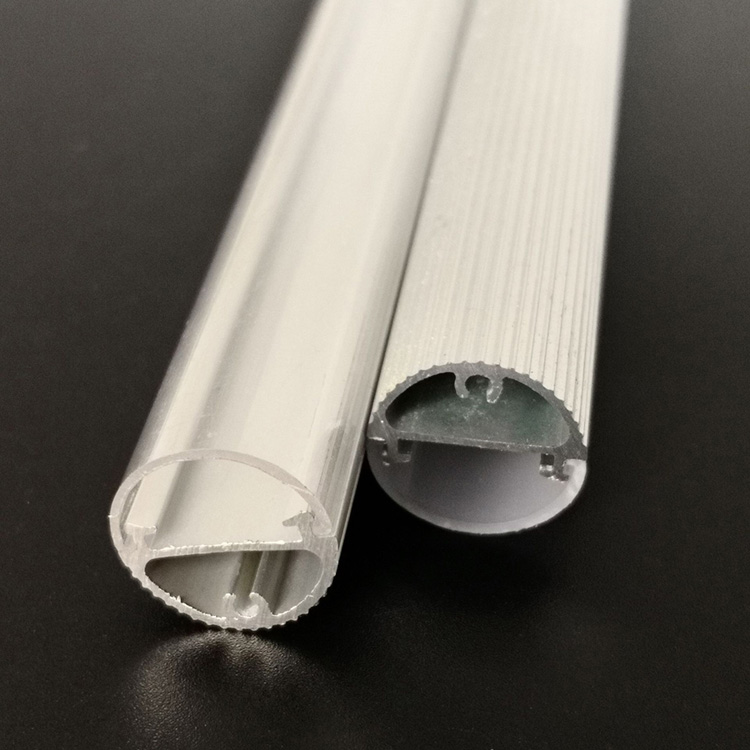

JE was established in 2017, mainly engaged in the production and manufacturing of LED tube housings and LED aluminum profiles, and enjoys a high reputation in domestic and foreign markets. Our products have reasonable prices and stable quality, and have been rated as "Quality Suppliers" by suppliers many times. The LED T5 housing is made of plastic cover or aluminum profile. The plastic cover is usually polymer materials such as polycarbonate or polyformaldehyde resin, which has the advantages of being lightweight, impact-resistant, durable, waterproof, dustproof, and heat-insulating. The aluminum profile material has the characteristics of high strength, corrosion resistance, good heat dissipation performance, stable performance, etc., and is more suitable for use in outdoor places. If you have any needs, please feel free to contact us.

Send Inquiry

In addition to the main LED tube housings, LED aluminum profiles and other linear lighting housings, JE can offer customized linear lighting housings according to clients requirements. Since its establishment, the company has been committed to providing customers with professional LED tube housing solutions. For this JE-23 LED T5 housing is almost the same as JE-22, The advantage of using plastic for the LED T5 housing is that, with the same number of internal light sources, it can carry more internal structures and is suitable for more customized needs; while the advantage of the aluminum alloy shell is that it is more efficient in terms of heat dissipation and corrosion resistance. It has advantages and is more suitable for outdoor use. In short, the material of the LED T5 housing is lightweight, has high protective performance and good heat dissipation. It can better protect the light source and is more suitable for various complex environments, such as indoor and outdoor places where people come into contact with each other.

Product Parameter (Specification)

|

Item NO. |

JE-23 |

|

Length |

600mm, 900mm, 1200mm, 1500mm, 2400mm or customized |

|

Tube |

T5 |

|

Diameter |

15mm |

|

PCB board size |

10*1mm |

|

Driver |

External or put in end caps |

|

Aluminum tube material |

6063-T5 aluminum alloy |

|

Aluminum tube color |

Silver |

|

Plastic cover material |

Polycarbonate |

|

Plastic cover color |

Frosted, Clear(transparent) or stripe. |

|

End caps |

Plastic |

Product Feature And Application

This JE-23 LED T5 housing is the another main style of T5 lamps, mainly used in factories, parking lots, hospitals, schools and more other public places.

Product Details

More details of this LED T5 housing:

Product Qualification

As a LED Aluminum Profile and LED plastic profile professional manufacturer, here are our main machines:

1.20 plastic extrusion machines

2.5 aluminum extrusion machines,

3.A professional integrating sphere to test whether the lamps made by our lamp kit can meet the various indicators required by customers,

4.A professional standard light source testing equipment for testing the light transmittance and other properties of plastic lampshades.

JE always focus on product qualification from aluminum and plastic raw material to extrusion production line, from samples quality control to mass production control, from strong perfect package to whole-heart service.

Deliver,Shipping And Serving

FAQ

Q1. How long is your lead time?

Re: For our regular items the lead time is about 3-5 days. For customized items, the lead time is about 25-35 days including tools making time.

Q2. How do you ensure quality?

Re: At first, we use new raw material all with environment protection certifications, please be sure we don’t use any re-product raw material.

Second, we have professional Quality Control department, both samples and finished products must be confirmed by QC before shipment.

Q3. How many days is the tool production of LED aluminum and plastic profile?

Re: Usually 7-15 days.

Q4. If OEM is acceptable?

Re: Yes, We have so various types of professional and technical personnel and enough machines that are very willing to accept OEM&ODM cooperation.

Q5. What is process of OEM order?

Re: Receiving drawing--Project manage confirm all production details with customer--Receiving tool production PO--Sales assistant proceed tool production--QC confirm samples are ready for shipping--Project manage confirm products with customer about every details-- start the regular order